Vehicles that once used mechanical systems—which were supplemented by hydraulic or electrical systems for functions like steering, ignition, lights, and audio entertainment—are now full of cutting-edge electronics. And with increased electronic capability comes an increased risk of electrically damaged circuitry caused by electrostatic discharge (ESD) and switching loads in power circuits and lighting systems.

ESD—characterized by fast rise times and high peak voltages and currents—can harm electronic control units (ECUs), infotainment devices, sensors, fuel injectors, powertrains, and dozens of other automotive subsystems. Circuit protection components are necessary to mitigate this kind of catastrophic damage.

Circuit protection components include a variety of devices such as varistors, fuses, inrush current limiters, gas-filled surge arresters (GDTs), and both positive temperature coefficient (PTC) and negative temperature coefficient (NTC) thermistors. These devices protect integrated circuits (ICs) and other components at the board level from overvoltage, overcurrent, overtemperature, and ESD. As a result, they boost the component’s lifetime and reliability, as well as lower maintenance costs.

In automotive electronics, transient surges can damage the engine-cooling systems, communication buses, valves, motors, hydrolytic controllers, etc. Therefore, it’s imperative that automotive designers implement safeguard mechanisms against ESD, surges, load dumps, and other threats.

Let’s start by looking at varistors, two-terminal semiconductor devices that provide overvoltage protection via voltage clamping. Varistors enhance circuit protection by changing impedance by orders of magnitude, and that enables automotive designs to boost power density as well as energy efficiency.

Varistors: Safeguard Against Transients

Zener diodes are commonly used for protection against load-dump surges. During the powering or switching of inductive loads, such as when the battery is disconnected while being charged, unwanted spikes (transients) can be generated. If not corrected, these transients are transmitted along the power line and can damage the vehicle’s electronic system.

Varistors are like Zener diodes in the sense that they allow lower-threshold voltages to pass unaffected, but they decrease resistance proportionate to the access voltage. Unlike Zener diodes, varistors operate in both directions.

Take the example of the MLA Automotive Series of varistors from Littelfuse that suppresses transient events across a broad range of voltage and temperature for applications encompassing vehicle power supply, control, and signal lines. The varistors conform to the IEC 61000-4-2 standard for electromagnetic compatibility (EMC).

Figure 1: Varistors change the impedance from a near-open circuit to a highly conductive level, clamping the transient voltage to a safe level. (Source: Littelfuse)

These circuit protection devices are manufactured from semiconducting ceramics. They are compatible with modern reflow and wave-soldering procedures. They come in a leadless, surface-mount package that affords the designer space savings over the larger footprint of plastic-housed components. The V26MLA0603NHAUTO varistor, for example, measures 1.6 × 1 × 0.8 mm and features an operating temperature range of –55°C to 125°C.

This is a voltage-dependent resistor that can handle a maximum surge current of 30 A and features a clamping current of 1 A along with a clamping voltage of 60 V. The maximum AC voltage rating that this multilayer varistor offers is 20 VAC, and its maximum DC voltage rating is 26 VDC.

The MLA Series devices are metal oxide varistors (MOVs), the most common clamping device that can operate across a wide range of voltages and currents. Unlike standard silicon carbide (SiC) varistors, MOV’s metallic oxide materials significantly lower the leakage current at normal operating conditions while clamping transients much faster.

Overvoltage and Overcurrent Protection

Another circuit protection device widely used in automotive electronics is a transient voltage suppressor (TVS) diode. TVS diodes protect communication buses, such as the controller area network (CAN) bus, from ESD, electrical fast transient (EFT), and other overvoltage transients.

TVS diodes absorb repetitive ESD strikes above the maximum level specified in the IEC61000-4-2 standard without performance degradation. And they safely dissipate the surge current with very low clamping voltages, according to the IEC61000-4-5 standard for surge immunity.

TVS diodes safeguard automotive electronics by providing secondary protection from transients induced by load dump and other transient voltage events. That allows automotive designers to save considerable cost and aggravation associated with component replacement.

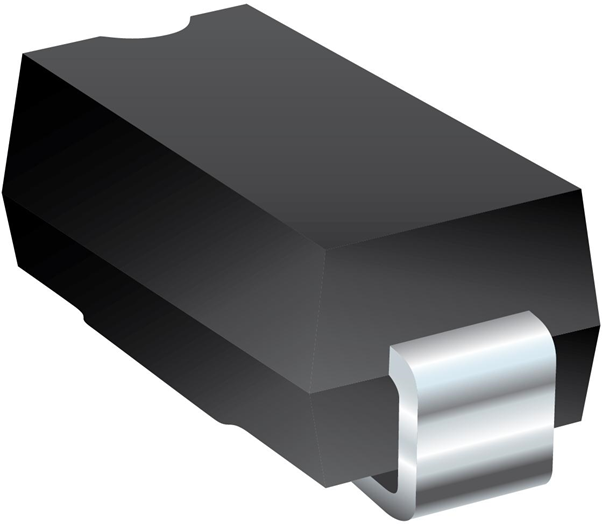

Below is an example of TVS diodes that Bourns has designed specifically for surge and ESD protection applications. The SMxJ-Q diodes feature a choice of peak reverse voltage ranging from 12 V up to 58 V and fast response times of less than 1 ps from 0 V to breakdown voltage.

Figure 2: The SMxJ-Q series of TVS diodes protects I/O interfaces and networking buses from overvoltage transients in vehicle electronics. (Source: Bourns)

The SMAJ-Q Series features 400-W power dissipation and a peak forward surge current of 40 A, while the SMBJ-Q diodes take power dissipation to 600 W and peak forward surge current to 100 A. Next, the SMLJ-Q Series offers 3,000-W minimum peak pulse power dissipation and peak forward surge current of 300 A.

If overcurrent protection is the concern, there are PTC resettable fuses from Bourns that feature a maximum current rating of 100 A and can operate at a temperature range of –40°C to 85°C. The MF-MSMF260-2 fuse from Bourns can be easily mounted on a PCB, and it prevents designers from constantly replacing the burned-out fuses.

Fuse Against Overheating

Fuses, common circuit protection devices in automotive electronics, allow components to withstand rapid temperature cycles and vibration by melting under overcurrent conditions, thus interrupting the current flow. For example, B72214S250K101 is a new edition to the NT series of ThermoFuse varistors from EPCOS, a TDK brand.

The circuit protection device comprises a disk varistor connected in series with a thermally coupled fuse designed to trip in the event of overheating due to the excessive overvoltage conditions. When the fuse trips, it disconnects the overheated varistor from the power circuit and prevents the potential of electrical fires.

Figure 3: The NT series of ThermoFuse devices comprises 14 mm and 20 mm-diameter disk varistors. (Source: TDK)

The outcome is a stronger thermal-resistant and flame-retardant capability. In addition to the two varistor terminal wires, the fuse device features a monitor output lead that can send a status signal. For instance, an LED can indicate that the fuse has been tripped.

The new ThermoFuse varistors in the NT series can absorb maximum surge currents with an 8/20 µs pulse between 6000 A and 10000 A at rated voltages between 130 VRMS and 750 VRMS. Furthermore, they feature a surge-current capability of 10000 A and a maximum energy-absorption capacity of 480 J for 2 ms.

Application-Tailored Protection

Circuit protection has always been a key ingredient in modern automotive designs due to extreme reliability demands and harsh operating environments. But the advent of advanced driver-assistance systems (ADAS), autonomous cars, and vehicle electrification is making protection against ESD, load dump, surges, and other threats far more critical.

At a time when automotive designs are transitioning from mechanical relays, solenoids, and switches to IGBTs, MOSFETs, and thyristors, the role of circuit protection devices has become vital in preventing catastrophic failures in automotive systems spanning from lighting to motor control and on-board battery chargers to networking buses.

Carefully review your automotive application and see which circuit protection devices adequately address the application’s needs. Next, evaluate key parameters like maximum surge current, peak power dissipation, and instantaneous forward voltage to ensure the creation of a highly reliable design.