In the process of factory automation, it is necessary to accurately control the operation of motors in machines and tools, and give early warnings when abnormalities occur, so as to reduce the downtime caused by machine failures. This article will show you the development, advantages, and disadvantages of various encoder technologies for motor control, as well as the product characteristics of capacitive encoders introduced by CUI Devices.

Magnetic encoders and optical encoders have their advantages and disadvantages

In the aspect of precision motion control, an encoder is an important component to convert mechanical motion into electrical signals. Encoders can be used in many applications such as automation equipment, industrial process control or robotic technology, and can provide data on position, speed, distance, and direction. At present, there are three main encoder technologies available in the market, including magnetic, optical, and capacitive encoders.

Magnetic encoders consists of a rotating magnetized disk with alternating magnetic poles and a Hall effect or magneto-resistive sensor, which works by detecting changes in the magnetic flux field. Magnetic encoders are durable and can cope with shock and vibration well without being affected by oil, dirt, and moisture. However, magnetic encoders are vulnerable to magnetic interference caused by electric motors and have a limited operating temperature range. Although many improvements have been made to magnetic encoders, their resolution and accuracy are usually lower than optical and capacitive alternatives.

Compared with magnetic encoders, optical encoders can provide higher resolution and higher accuracy. The optical encoder consists of an LED light source (usually an infrared light source) and photodetectors located on opposing sides of an encoder disk made of glass or plastic. Although optical encoders have dominated the motion control market for decades, because of reliance on "line of sight", they are particularly vulnerable to dust, dirt and oil stains, as well as vibration and extreme temperature. In addition, optical encoders will consume up to a 100 mA current in operation, and their life will eventually be limited by LEDs.

Capacitive encoders provide better accuracy and durability

The capacitive encoder consists of three main components: a rotor, a stationary transmitter, and a stationary receiver. The rotor contains a sinusoidal pattern, and as the rotor rotates, the high frequency reference signal of the transmitter is modulated in a predictable way. The encoder detects the change of capacitance reactance on the receiving board, and uses a demodulation algorithm to convert it into an increment of rotary motion. Capacitive encoders are more durable than optical encoders, can withstand various environmental contaminants, and can hold-up much better to vibration and extreme temperatures. In addition, without LEDs, capacitive encoders have a longer lifetime, smaller footprint, and lower current consumption (6 to 18 mA) compared with optical encoders. It is not affected by magnetic interference and electrical noise, and is as robust as a magnetic encoder, but has higher accuracy and resolution.

In view of the digital characteristics of capacitive encoders, capacitive encoders also provide greater flexibility, allowing users to change the resolution of encoders. When using other technologies, the resolution is determined by the encoder disk, which means that the optical or magnetic encoder must be replaced every time a different resolution is needed. The programmable resolution available in capacitive encoders not only can be used for system optimization (especially when designing PID control loops), but also reduce inventory because a single product model can be used in many applications. Capacitor technology also allows for the digital setting of index pulses and alignment of encoders commutated by BLDC, while its built-in diagnostic capabilities provides designers with access to system data for quick troubleshooting in the field.

Regardless of the system requirements, capacitive encoders can provide a versatile, cost-effective, and reliable alternative to optical or magnetic sensing technology. Capacitive encoding not only can provide excellent performance in accuracy and reliability under any environmental conditions, but also its inherent digital operation can provide programmability and enhanced diagnostic capabilities, while still being compatible with traditional encoder functionality.

Flexible resolution programming can reduce inventory

Since CUI Devices introduced the first generation of capacitive encoders in 2006, its AMT series has been proved to have high reliability and accuracy and can solve many application problems encountered in optical and magnetic technologies. Using capacitive sensing technology, CUI Devices' incremental, absolute, and commutation AMT modular encoders can provide highly durable solutions without sacrificing accuracy. The AMT series has up to 22 programmable resolutions and operates in the temperature range of -40 to 125℃, providing engineers with greater flexibility in the prototyping design process, and purchasing managers can greatly reduce the number of specifications required in production.

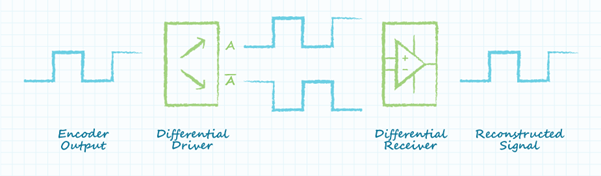

Encoder output driven by differential driver and reconstructed by receiver

CUI Devices offers a range of standard incremental encoders, absolute encoders, and commutation encoders for brushless DC motors. CUI Devices' AMT encoders are available in radial and axial configurations and offer a variety of output signal types, including single-ended, differential line drivers, SSI, SPI, RS-485, etc. CUI Devices' family of AMT encoders has a variety of choices to meet the needs of almost any application.

Due to the characteristics of the underlying technology, the family of AMT encoders is very robust, unlike optical encoders, which easily interfere with optical signals due to dust or particles attached to glass discs, and inside which the LED easily burns out over time. AMT encoders use capacitive technology, so LED or line-of-sight conditions are not required. Dust, oil stains, etc, common in industrial environments will not affect AMT encoders, which are also very suitable for use on motors or gear assemblies that need to seal the whole device in oil.

In addition, AMT encoders do not need the glass disk of the optical encoder, and will not be reduced in efficiency due to factors such as falling, vibration or shock, and AMT encoders have no wear components, which means that the number of rotations is not limited, so they are more durable.

Diversified product lines meet different needs

CUI Devices' family of AMT encoders has a variety of choices, and the resolution can also be adjusted as required. For example, each AMT10 or AMT10E encoder has a 4-position DIP switch on the backside. Users can select from 16 resolutions only by adjusting the position of the switch. Other AMT series encoders can use AMT programming cables and PCs to adjust the resolution. CUI Devices' AMT Viewpoint™ software allows users to configure a variety of specifications according to the series, including resolution, direction of rotation, motor pole pairs, and zero position. AMT Viewpoint will help customers determine the waveform plots and calculated pulse width values, which will be automatically adjusted when selecting the resolution. All AMT encoders can also be customized according to custom ordered pre-configured to any available resolution.

CUI Devices offers AMT10 and AMT10E series, AMT11, 20, 21, 22, 23, and 31 series, AMT12 series, AMT13, and 33 series capacitive encoders.

Conclusion

Compared with magnetic and optical encoders, capacitive encoders have the characteristics of higher accuracy and resolution, more durability, etc. They are quite suitable for use in harsh factory environments. CUI Devices has introduced many series of capacitive encoders, which will meet your different needs in practical applications and deserve your further understanding.