Today’s world is immersed in high-speed, digital electronics, and as communication speeds increase with highly sensitive environments, it has become critical to employ isolation tactics for safety and reliability.

Though primarily seen in the industrial, medical, and aerospace fields, more and more applications are now requiring extra layers of protection. Most isolated digital applications include electromagnetic-interference mitigation by removal of shared grounds, protection against hazardous voltage levels, and keeping data transmission transient-free, which, depending on the application, could cause data corruption, lost connections, and potentially unsafe and unpredictable operating conditions.

It’s no secret that isolation helps with these things, and onsemi’s new Digi-Max family of off-chip ceramic digital isolators provides many advantages over traditional isolation methodologies such as speed, transient immunity, temperature, and overall lifetime performance.

A background on optical and digital isolation technologies

Isolation has taken many forms over the past 60 years, starting with analog, optics-based isolation (which still holds strong in today’s industry), and, more recently, digital isolation incorporating technologies such as CMOS and RF transmission.

In general, digital isolation outperforms opto-isolation due to higher switching rates and longer-lasting internal components. Opto-isolator LEDs are generally the culprit when it comes to failures due to thermal stress over time, susceptibility to peak transient currents, diode current limitations, and overall component lifetimes. Digital isolation primarily incorporates magnetic and capacitive coupling across an internal barrier to transfer signal information rather than light-sensitive components, although some digital isolators do incorporate some optical components as well. Also, digital isolators contain as many as six channels in a single package, making them ideal for multi-channel data buses.

Generally speaking, digital isolators occupy a smaller footprint and are commonly incorporated onboard other ICs used for sensitive or critical communication, saving size and cost as well. Galvanic isolation is considered the safest form of isolation, as it provides transfer of information from one circuit to another without any electrical connection or leakage paths.

Though optocouplers are one of the most common forms of galvanic isolation and thus safer than many types of digital isolators involving magnetics, they are typically the slowest, bulkiest, and relatively power-hungry, making them non-ideal for high-channel-count and high-speed applications. See Figure 1 for a visual comparison of opto-isolation versus digital isolation.

Most digital isolators feature on-chip capacitive technology, which contains thin insulation barriers and materials that are susceptible to damage from electrical overstress and electrostatic discharge. Typically when a digital insulator becomes damaged, it can lose its ability to isolate between two power planes. onsemi’s Digi-Max family of digital isolators is not only galvanically isolated and provides safety levels of traditionally safer opto-isolation but also operates at the high speeds needed for today’s communication applications. In addition, if the Digi-Max isolators do become damaged, they still intrinsically maintain a safe insulation barrier, resulting in safer failure modes and operating conditions. Digi-Max isolators utilize a patented galvanic off-chip capacitor isolation technology coupled with optimized IC design that allows it to achieve high insulation and noise immunity.

The Digi-Max advantage

The NCID9XXX family of Digi-Max devices incorporates a ceramic substrate that allows for insulation barrier thicknesses of over 0.5 mm and is rated for 8-mm external creepage and clearance distances, reaching safety-reliability levels that are seen with opto-isolation technologies. With air having a breakdown voltage of 3,000V/mm, the Digi-Max’s 0.5mm isolation thickness guarantees a working voltage of 1,500V by design, even if no dielectric material were present between contact points. With a maximum working insulation voltage of 2,000 Vpeak, Digi-Max provides a longer-lasting level of protection when compared with some other digital insulation barriers and the LED degradation of optocouplers. And beyond the high level of safety and reliability, the NCID9xxx family of multi-channel, bidirectional devices contains other useful features such as:

• Output enable and over temperature detection

• Extended temperature ranges (-40˚C to 125˚C)

• On-off keying technique used for signal modulation

• AEC-Q100 qualification (pending)

• Regulatory approval for UL1577 (5,000 Vrms for 1 minute)

• Consistent performance across temperature, over time, and between devices

• Common-mode transient immunity (CMTI) of over 100 kV/µs

• High-speed data transmission up to 50 Mbits/s

Figure 2 shows a single-channel–version block diagram of the internal layout in these Digi-Max isolators.

Let’s quickly take a look at the CMTI rating: CMTI is defined as the maximum rate of change between common-mode voltage potentials that the isolation barrier can withstand, or basically how well the insulation can reject fast and powerful transients. Although capacitive-technology blocks direct current, common-mode rejection can be problematic in capacitive isolation, as the common-mode noise and the transmitted signal share the same path. Patented design techniques, including techniques enabled by the off-chip package technology enables superior noise immunity to achieve 200kV/us typical CMTI performance.

While the Digi-Max family of devices generally comes at a cost premium, the reliability and safety gained from the off-chip capacitive isolation can be well worth it. Figure 3 shows a close-up view of how Digi-Max’s off-chip capacitance differs from on-chip capacitance.

Typical applications for isolation

Applications requiring isolation for on-board or off-board peripherals include pulse-width–modulation control, industrial fieldbus communications, serial interfaces with microprocessor systems such as SPI, data acquisition, and voltage-level translation. One of the most common system configurations utilizing isolation between a SPI bus master and slave device where the slave device has its own local circuitry and is located offboard as a peripheral device.

Figure 4 shows a typical design where a daughter card is connected through a SPI bus interface. The two boards use different power supplies where it’s important to isolate the SPI signals and any ground noise generated by the daughter board.

quad-channel isolator NCID9311

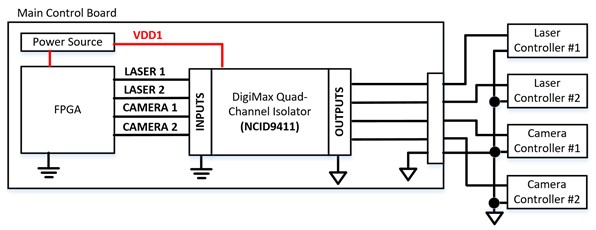

Another example requiring isolation may be for off-board peripherals that contain sensitive, digital signals used for fast triggering. Figure 5 shows an imaging application in which a field-programmable gate array has many fast-trigger signals wired to external components like lasers and cameras (on/off illumination for a laser or on/off exposure for a camera). These devices have their own power sources that must remain separate from the processing core to prevent noise or transients, and so the trigger signal must be isolated on each end.

Conclusion

While there are many other applications for isolation, each methodology has its benefits and drawbacks. While opto-isolation is generally cheapest, it’s relatively slow and poses challenges with performance degradation over temperature and time. On-chip capacitive isolation provides higher speed and performance at a reasonable cost but can’t deliver the safety and reliability of Digi-Max’s off-chip isolation.

Isolation is not only an insurance policy but, in many cases, a last line of defense for safety, sensitive circuitry and data. onsemi’s Digi-Max family of devices has shown that this higher level of reliability and safety can be achieved without sacrificing speed or performance. The high reliability of onsemi’s Digi-Max offers a new path for designers using traditional optocouplers to migrate to digital isolation technology without comprising on safety insulation.

(Note: CMTI comparison was done with SiLabs Si860x and TI ISO72x devices)