Learn more about how to select the appropriate microphone technology for your next project in this blog post from CUI Devices.

Perhaps you remember the marketing campaign from a few years ago with the phrase, "Can you hear me now?" More and more devices being designed today, from wearables to home assistants, are being asked to "hear" their environment. The correct microphone makes it possible for applications to accurately capture almost any sound, with the two most common technologies used for constructing microphones being MEMS and electret condenser. Although the two technologies work on similar principles, there are many use cases for choosing one over the other. With that in mind, we will review MEMS and electret condenser microphone basics, compare the differences between the technologies, and outline the advantages of each solution.

MEMS Microphone Basics

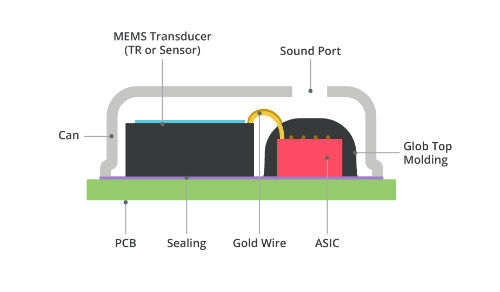

MEMS microphones are constructed with a MEMS (Micro-Electro-Mechanical System) component placed on a printed circuit board (PCB) and protected with a mechanical cover. A small hole is fabricated in the case to allow sound into the microphone and is either designated as top-ported if the hole is in the top cover or bottom-ported if the hole is in the PCB. The MEMS component is often designed with a mechanical diaphragm and mounting structure created on a semiconductor die.

Typical MEMS microphone construction

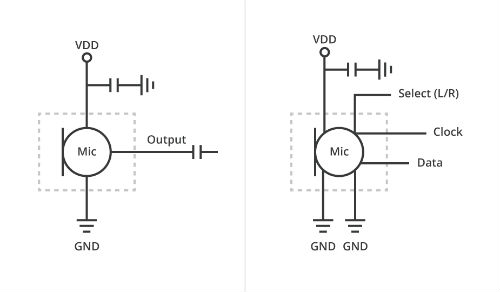

The MEMS diaphragm forms a capacitor and sound pressure waves cause movement of the diaphragm. MEMS microphones typically contain a second semiconductor die which functions as an audio preamplifier, converting the changing capacitance of the MEMS to an electrical signal. The output of the audio preamplifier is provided to the user if an analog output signal is desired. If a digital output signal is desired, then an analog-to-digital converter (ADC) is included on the same die as the audio preamplifier. A common format used for the digital encoding in MEMS microphones is pulse density modulation (PDM), which allows for communication with only a clock and a single data line. Decoding of the digital signal at the receiver is simplified due to the single bit encoding of the data.

Left: analog MEMS microphone application schematic Right: digital MEMS microphone application schematic

Electret Condenser Microphone Basics

Electret Condenser Microphones (ECM) are constructed as shown in the figure below.

Typical electret condenser microphone construction

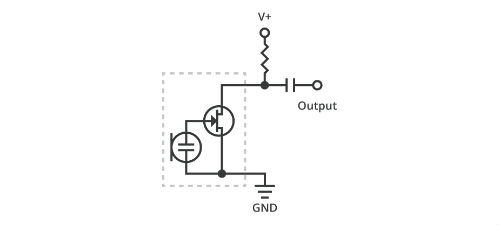

An electret diaphragm (material with a fixed surface charge) is spaced close to a conductive plate, and similar to MEMS microphones, a capacitor is formed with the air gap as the dielectric. Voltage across the capacitor varies as the value of the capacitance changes due to sound pressure waves moving the electret diaphragm, ΔV = Q/ ΔC. The capacitor voltage variations are amplified and buffered by a JFET internal to the microphone housing. The JFET is typically configured in a common-source configuration, while an external load resistor and dc blocking capacitor are used in the external application circuit.

ECM application schematic

Differences in Microphone Technologies

There are many considerations when selecting between an ECM and MEMS microphone. The market share for MEMS microphones continues to grow at a rapid pace due to many advantages provided by this newer technology. For instance, space constrained applications will find the small package sizes available for MEMS microphones attractive, while a reduction in both PCB area and component cost can be realized thanks to the analog and digital circuits included in the MEMS microphone construction. The relatively low output impedance of analog MEMS microphones and the outputs from digital MEMS microphones are ideal for applications in electrically noisy environments. In high vibration environments, the use of MEMS microphone technology can reduce the level of unwanted noise introduced by the mechanical vibration. Furthermore, semiconductor fabrication technology and the inclusion of audio preamplifiers enables manufacturing MEMS microphones with closely matched and temperature stable performance characteristics. These tight performance characteristics are particularly beneficial when MEMS microphones are used in array applications. During product manufacturing, MEMS microphones can also be easily handled by pick and place machines and tolerate reflow soldering temperature profiles.

Although MEMS microphones are growing rapidly in popularity, there are still applications where an electret condenser microphone may be preferred. Many legacy designs have used ECMs, and thus, if the project is a simple upgrade to an existing design, it may be best to continue using an ECM. Options for connecting an ECM to the application circuit include pins, wires, SMT, solder pads and spring contacts, giving engineers additional design flexibility. If protection from dust and moisture is an issue, it is easy to find ECM offerings with high Ingress Protection (IP) ratings due to their larger physical size. For projects requiring non-uniform spatial sensitivity, ECM products are available with intrinsic directionality, either unidirectional or noise canceling, while the wide operating voltage range of ECMs may be the preferred solution in products with loosely regulated voltage rails.

Selecting the Appropriate Microphone Technology for Your Project

The decision to use electret condenser versus MEMS microphones will be dependent upon the requirements of your project. While MEMS microphones continue to grow in popularity due to their many inherent advantages, ECMs are still used in a variety of applications thanks to a wider range of packaging and directionality options. Regardless of the technology chosen, CUI Devices will continue to develop and offer a wide range of microphone products to allow your project to 'hear' the required sounds.