Each year, untold millions of electronic devices are destroyed or crippled by electrostatic discharge (ESD). Invisible to the naked eye, ESD can affect electronic devices at any stage, including device or board manufacturing, testing, assembly, shipping and even ordinary use. Memories, including flash cards and SSDs, PLDs, FPGAs, ASICS and SOCs, are particularly susceptible to ESD damage.

ESD results from charges collecting on a surface. The surfaces of nonconductive materials develop equal and opposite charges when they come in contact, move against each other and then separate quickly. An electric field surrounds a nonconductive material once it is charged. Eventually, the amount of charge exceeds the insulating ability of the air and a spark jumps to the conductor. The spark introduces currents in the conductor that can damage or destroy a sensitive device.

ESD sparks occur in many different environments: A person walking on a carpeted floor can generate high-static voltages due to triboelectric charging, and voltages as high as 20 kV have been reported. Likewise, machines that use plastic parts can hold an electrostatic charge due to the plastic rubbing against other plastic parts.

Electrostatic Discharge Sensitive: A Growing Electronics Problem

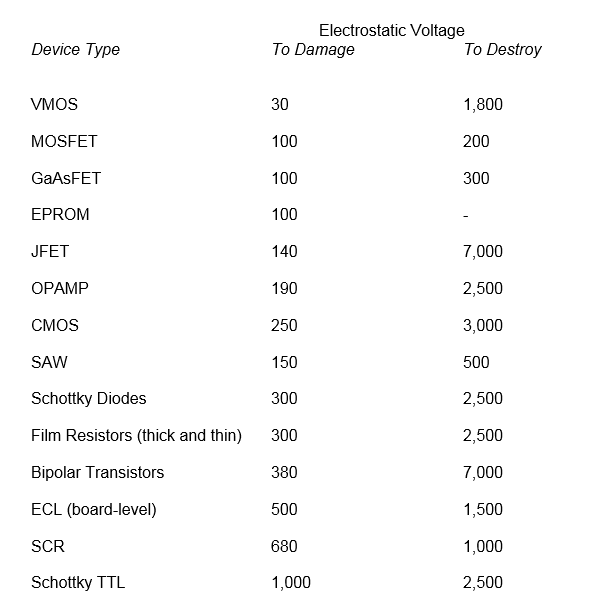

Many electronic components are sensitive to electrostatic voltage as low as 30 V and current as low as 0.001 A — far less than one can feel, hear or see (Table 1). Increasingly thinner layers in semiconductor devices have made ESD a growing threat. CMOS devices with small device geometries are particularly susceptible to failure. In wireless applications, such as GPS, WLAN or Wi-Fi devices, the antenna can act as a low-impedance path for ESD to enter the system and damage downstream circuitry.

Preventing ESD-induced failure starts at the circuit design stage. Grounding and layout techniques play an important role in preventing ESD effects. It’s important to apply proper design guidelines and choose components that have a high ESD-tolerant voltage capability. Use devices of the right speed to achieve a desired function because unnecessarily high-speed devices can generate unwanted radiation.

ESD Suppression Techniques

A proven way of suppressing ESD energy is placing transient-suppressor diodes at critical circuit points. An ESD diode will “clamp” the voltage, protecting downstream circuitry from voltage greater than the clamping voltage. Unfortunately, because ESD diodes are connected in parallel to the signal trace, they add some parasitic capacitance to the system. ESD device capacitance is particularly important in high-speed interfaces because capacitance must be minimized to maintain signal integrity.

While using transient suppressor diodes to protect an input or output, it’s important to keep the transient suppressor as close as possible to the terminals. Avoid PCB traces and long leads because they possess parasitic inductance and will cause voltage overshoots and ringing problems if an ESD transient wanders into the circuit.

Many ESD problems can be minimized with a well-planned and routed PCB. Electrostatic and magnetic lines of flux exist in every circuit. If board routing encloses large loop areas, the conducting paths will enclose more of the magnetic flux, which, in turn, will induce current in the loop due to the loop acting as an antenna. This loop current will cause interfering fields that will affect components in the circuit. One way to reduce loop areas is to route supply and ground lines as closely together as possible.

Use a low-impedance ground in the board design so that any electrostatic discharge currents can easily flow to ground without finding other low-impedance paths through electronic devices. A ground area, preferably a ground plane, will reduce ESD effects. Unused areas on a PCB should be converted into ground plane. During placement, ensure that sensitive electronic components are positioned away from potential ESD sources.

How Do You Prevent Electrostatic Discharge?

Careless PCB handling is responsible for many ESD-induced failures. A highly effective way to protect against ESD is to wear a wrist strap that connects to ground. A wrist strap typically consists of an elastic strap with a snap fastener and a ground lead.

It’s also a good idea to provide a trace around the PCB edge to serve as a ground-connected guard trace. PCB routing should be designed to ensure the largest possible spacing between adjacent traces so that ESD pulses don’t arc between adjacent traces and propagate. In most devices, protection devices should be used between the device pin and connector pin. Additionally, when designing logic circuits, try to avoid edge-triggered devices. These inputs can cause system malfunction if an ESD transient finds its way into the circuit. Level-sensing logic with a validation strobe can be used to improve circuit ESD immunity.

How to Handle Electrostatic Sensitive Devices

ESD-sensitive devices should be stored in antistatic tubes, bins or conductive foams specially designed for the purpose. The enveloping conductive surfaces, in direct contact with the sensitive devices, will bleed off of accumulated charges, preventing voltage differences between pins of the device and bar voltage buildup. A metallized polythene bag acts as a Faraday cage to protect devices stored within from electric fields caused by charged bodies in the vicinity. Cover communication connectors with static dissipative material when not in use to prevent charge buildup. Also use antistatic material on worktables and floors in assembly areas to prevent generation of static electricity due to walking and related activities.

Managing the local environment can also help reduce ESD risk. A humid atmosphere provides a means to discharge any atmospheric floating charges to ground and provide protection against static electricity buildup compared with dry air conditions. Air ionizers neutralize free charges and help in reducing ESD problems in assembly lines. Avoid tools with plastic handles because the handle can become charged.

Takeaways

Overcoming ESD failures requires a total commitment to control techniques at the design, handling, assembly, testing, system integration, shipment and operation stages.

It’s important to define the level of ESD protection required for various types of components. Identify ESD sensitive items. Take design precautions to provide adequate protection for such components. Ensure that antistatic precautions are faithfully observed.

Establish an ESD control program. Identify potential problem areas, study failures and develop methods to overcome them. Train workers at all levels and educate them on ESD damage and measures to prevent the same.

ES control should be a continuous process, and there are long-term benefits in terms of loss prevention and overall cost benefits.

Table 1:Component Sensitivity to ESD