Following generations of custom bench-top instrumentation, the transition continues toward modular instruments with more flexibility, software control and, smaller form factors. However, lower power consumption, while still meeting noise and measurement accuracy targets, remains a challenge.

One element of the change is to enable mobility. The large custom and rack-based systems have limitations from a logistical point of view. The breakup of cabinet/desktop equipment into smaller nodes enables custom configuration and optimizes the instruments for the environment and geography of the test site or subject. Improving the mobility of the measurement node reduces wiring to transducer cables and eliminates connecting many cables to the correct input on a large rack—all of which minimizes headaches in measurement installation. Despite the changing form factors, the need for optimum test performance, certainty, and accuracy remain.

Application areas

A modular platform instrument with high dynamic range is analogous to the measuring tape of 21st century advanced development and innovation across a broad spectrum of industries.

• Testing within research and development fields of material science, such as the structural analysis of everything from the blades of a windmill to the health, well-being and electrical output of its turbine.

• Measuring the outputs of strain/piezo transducers, conditioning those voltages and enabling quantitative analysis for structural health and materials development, and providing clear measurement without interference.

• Measurements for automotive cabin noise applications that can apply to the placement of digitizing microphones during prototype development, right through to faster and more accurate control loops to increase production throughput on the factory floor.

• Electrical testing:

- Audio measurement enabling the development of advanced microphone modules and speakers for voice-activated control and operation.

- Electrical test within ATE for both passive and active electronics, where parametric measurement accuracy and speed relate to the cost of the test.

• Mapping neural paths and measuring electrical signals to gather brain function data. Here clear needs are for lower bandwidth, higher dynamic range, low power and a smaller form factor.

These wide ranging applications have equally wide ranging channel counts. Standard 8-channel modules in industrial applications extend to 512 channels and beyond for an EEG measurement. Scaling the front-end measurement design to a large number of channels, while maintaining simultaneous sampling is key. It is the basis for the data that guides a generation of research, development, production and end operation.

Creating smaller form factor housings, whilst holding measurement channel density requires power efficiency. Increasing the dynamic range of the analog-to-digital converter (ADC) and the chain which precedes it to 110 dB, while keeping current consumption in check is a constant battle. Balancing dynamic range, input bandwidth, and current consumption isn’t easy.

A new ADC subsystem supported by the capabilities of the AD7768 and AD7768-4 has emerged. It provides the capability to digitize to wider bandwidths with higher accuracy than before, and to do so with fidelity and synchronised sampling across multiple channels. It also provides tools to ease thermal challenges and strike the right balance of dynamic range, input bandwidth, and current consumption in high dynamic range modular-system design.

Reconfigurable thermal footprint, software programmable measurement bandwidth

The AD7768 can adapt to the measurement situation. Heat, decreasing air space, and the absence of active cooling are all constraints of modular instruments, which the AD7768 eases using in-built operating modes for FAST, MEDIAN and ECO power scaling. For a given input bandwidth, the user may decide to expend more or less power, reducing heat within the module. An example would be digitizing over an input bandwidth of 51.2 kHz. Such a bandwidth is popular for FFT-based analysis as it provides an integer bin size within the FFT output. The AD7768 features a brick wall digital filter that frames that required input bandwidth. A low-ripple passband and a steep transition band combine with full attenuation at frequencies just beyond 51.2 kHz, meaning there is no fold back from around the Nyquist frequency. For the AD7768, the user can chose to operate in either FAST or MEDIAN mode. The decision is between current consumption and dynamic range. Specifically, which is more constrained for the system. Let’s take a look:

MCLK = 32.768MHz, Low ripple passband filter (“Brick Wall”), 128ksps data rate for each mode, digitising 50kHz of input bandwidth with a 1kHz input sine wave at -0.5dB down from full scale. Figure 1 and Figure 2 show the comparison for the ADC performance: an outstanding low distortion digital version of the analog input sine wave. Moving to median mode allows reduced current consumption in return for compromising on noise and dynamic range by 3dB.

Table 1. Digitizing and creating an FFT for 51.2 kHz bandwidth. Choose highest dynamic range or lowest current consumption

1Note, some vendors express this number as SNR (shorted input noise). AD7768 tests with a full sine wave, exercising full reference range required for true SNR.

2Includes pre-charge analog input buffers. Pre-charge buffers reduce the analog input current vs input amplitude and make the analog inputs easier to drive for the preceding driver amplifier. The AD7768 delivers a distinct benefit in distortion with pre-charge buffers on.

In the instance of a classical 51.2 kHz measurement bandwidth, the user can choose to reduce current or maximize dynamic range of the ADC. Not only does the power scaling apply to the ADC, but there is also a knock-on effect to the driver amplifier circuit prior to the ADC. As shown in Figure 3, the subsystem also includes a driver amplifier, typically including signal conditioning for anti-aliasing.

Figure 3. ADC Subsystem Power scaling: The driver amp footprint can be repopulated with lower current amplifiers in conjunction with power scaling the ADC

A selection of amplifiers with differing power consumption can be paired with each of the power modes. The table illustrates that an initial design for FAST mode can be scaled later for use in either the MEDIAN or ECO modes with the same base footprint, but re-purposed for lower current consumption.

Table 2. Mapping ADC power modes to effective driver amplifier solutions

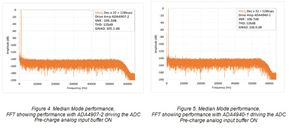

Scaling to a lower power amplifier with median mode helps reduce current consumption further. The performance using either ADA4907-2 or ADA4940-1 in median mode is illustrated by Figure 4 and Figure 5 when digitising for AC and DC over 50kHz input bandwidth.

Having the ability to tune and scale the power consumption of the measurement subsystem enables two benefits: embedded power scaling flexibility and the ability to create a base platform design that can be adapted for different measurement bandwidths, performance points, and end-measurement markets.

Software configurable input bandwidth and latency, and applying it to groups of channels

Not only can the AD7768 be used for scaling the current consumption and dynamic range of the ADC, there also exists configurable filtering, which can be adapted to the measurement situation. Brick wall, low-ripple filters are great for providing gain accuracy over a wide frequency range. Their drawback is a long integration/averaging time. As a result, group delay is relatively large for the AD7768, in the range of 34 data cycles before you see the digitized version of the analog input. To give a relative timescale, running in FAST mode at 250 ksps, each data conversion cycle is 4 us, so the group delay is 136 us. This may not be tolerable in control loops, or in applications that may value fast response above gain accuracy over frequency. To enable these high dynamic range measurements for control loops, the Sinc 5 filter path is used.

This path reduces the group delay by a factor of 10 relative to the wideband filter.

Figure 4. Comparing the group delay of Sinc 5 filter with wideband filter. Sinc 5 provides a fast response to input changes on analog input, suited to control loop applications where minimizing the loop latency is key. (The green dot represents the sample at the group delay time, the pink dot indicates a final settled value from each filter.)

A useful capability of the AD7768 is that it can allow a user to mix the type of filters among the channels. Each ADC may be assigned to one of two groupings of channels. Each group can then be assigned to one of the two filters and its speed set via one of six available decimation rates. This functionality enables different measurement types to be completed within the eight ADCs and allows them to be configured via software setting similar to the scenario where each of the ADCs were discrete. An example scenario is when monitoring a significant industrial asset. The user may wish to measure DC output from a 4-20 mA transmitter or voltage output transmitter at the same time as measuring the vibration sensor on another analog input channel. The DC response can be read from the transmitter and fed to the control loop, while the vibration is being measured on a separate, but simultaneous channel. This mix of input bandwidth and latency capabilities provides the ability for custom, high-value instrumentation in an industrial setting, doing more than just running the process variables, but integrating balance of plant vibration information overlaid.

Figure 5. Configure different ADC channels for different filter types. Two groups, A is using wideband, B Sinc. The decimation rate for each group may also be configured over SPI.

High performance with scalable high speed and low power enable modern form factors and use cases

The move from larger, stationary instrumentation to more mobile and flexible devices continues to gain popularity. They offer valuable potential for advanced development and innovation in a wide range of industries, markets and applications. While challenges such dynamic range, input bandwidth, and current consumption exist, advanced ADCs are helping to mitigate them and give designers a tool with greater capabilities than before.

About the Author

Michael Clifford is a member of the Linear and Precision Technology applications team at Analog Devices Inc. (Limerick, Ireland). He has worked for Analog Devices since 2004 and is focused on precision analog-to-digital converter products, in particular those using the Sigma Delta topology for both precision DC and AC measurement. He holds a Bachelor’s degree in Electrical and Electronic Engineering (BEEE) from University College Cork (UCC).