If your IoT application needs a variety of sensors and a powerful IoT connected processor as well as a quick path to a working prototype, then TE Connectivity’s (TE) Sensor Mezzanine Board and SD 600eval are the perfect solutions.

Introduction

Sensors are the eyes and ears of the Internet of Things (IoT). Without sensors where would the information come from that drives big data analytics key to IoT applications? Environmental sensors help drive energy efficient heating and cooling in smart buildings, while sensors in large agricultural applications test for humidity and soil conditions to drive efficient crop care, pest detection, harvesting and even transportation. Opportunities for transforming sensor data into knowledge that drives new businesses and business models are growing, so getting your new idea to market first can be the most important element in the success of a new IoT product.

One of the best ways to speed your time-to-market is to use existing development hardware with working code and high-level operating systems and applications support. For IoT applications this usually means obtaining a standard processor board with Android, Linux or Windows IoT core already running. A sensor expansion board with a wide range of sensor functions – environmental and positioning – that is compatible with the main processor board would provide a complete system from which to develop your applications. Using the Arrow SD 600eval processor board and the TE Connectivity (TE) Sensor Mezzanine Board could be just the solution to develop your IoT solutions in record time.

Using a Sensor Development Board to Speed Your Design

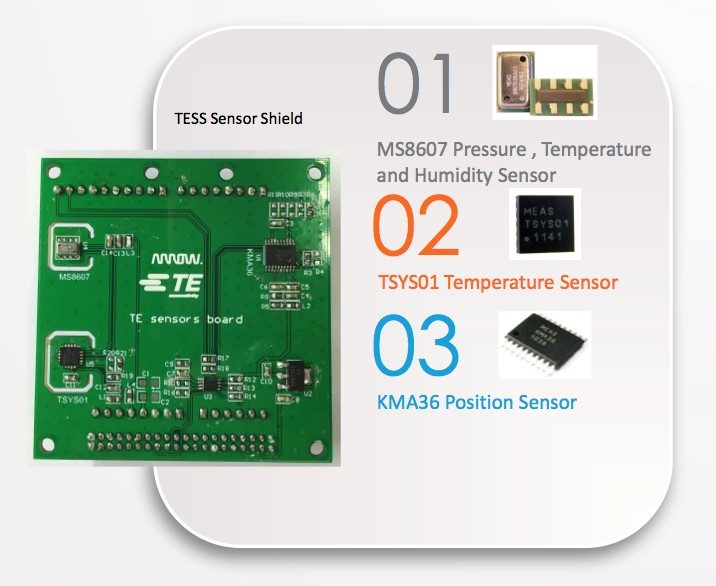

One of the fastest ways to get your design underway is to start with a development board that hosts the sensors you want for your design. This allows you to begin software development early, before you have the final form factor for the target hardware. With the rise of standard form factors for development kits, like the popular 96board standard, it has become much easier to find main boards, like the Arrow SD 600eval, with the processing power, on-board memory and peripheral set needed in complex IoT applications. TE’s Sensor Shield development board, shown in Figure 1 below, houses three popular sensor devices in a standard form factor compatible with the 96board standard.

Figure 1: TE’s Sensor Shield Development Board (Figure from Mezzanine PDF)

The sensors available on the TE’s Sensor Shield include the MS8607 Pressure, Temperature and Humidity sensor, the TSYS01 Temperature sensor and the KMA36 Rotational and Linear Position sensor. These sensors use standard serial interfaces making them easy to connect to a microcontroller and advanced features ideal for Internet of Things applications.

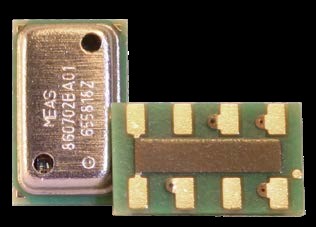

The Compact MS8607 Combination Sensor

In many IoT applications, small size and low power are critical requirements. A combination sensor that delivers pressure, humidity and temperature in a small package can be an excellent fit for size and power constrained applications. TE’s MS8607 is not only compact, using an ultra-small 5 x 3 x 1 mm QFN Package, show in Figure 2 below, but also offers a wide operating range of 10 to 2000 mbar pressure, 0% RH to 100% RH humidity and -40 to 85 oC temperature. TE’s MS8607 also provides excellent resolution for common IoT applications with 0.016 mbar, 0.04% RH and 0.01 oC. The supply voltage operates over a wide range, from 1.5V to 3.6V, to support low power operation. The I2C serial interface makes it easy to connect the MS8607 to a standard microcontroller.

Figure 2: The Compact TE’s MS8607 Combination Sensor in a 5 x 3 x 1 mm QFN Package

The high resolution pressure feature combined with high pressure, humidity and temperature (PHT) linearity makes the MS8607 an ideal candidate for environmental monitoring such as an altimeter in smartphones, tablets and PCs, as well as PHT applications such as heating, ventilation and air conditioning (HVAC), weather stations, precision 3D printers, home appliances and humidifiers. The MS8607 is manufactured using a proven MEMS technology that has been widely used for over a decade.

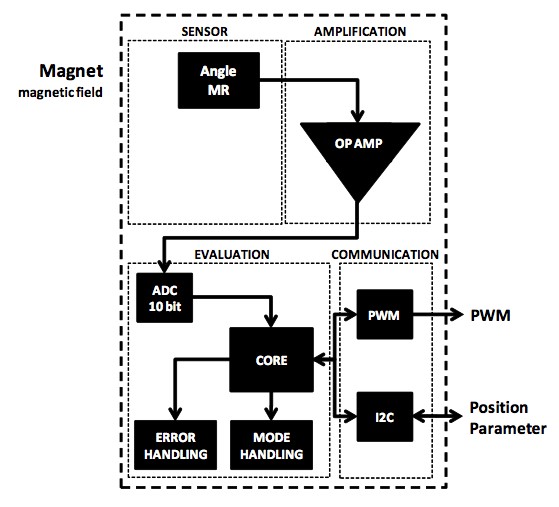

The High Precision KMA36 Rotational and Linear Position IC

Position sensing can be a critical element in industrial IoT applications where the position of a mechanical element such as a motor, valve, or robot arm controls a complex process. Often in these applications, contactless operation, high precision, resistance to wear and tolerance to changes in the environment are also key requirements. TE’s KMA36 is a highly reliable, high-precision, universal magnetic position sensor IC. It provides precise rotational or linear measurement with a resolution up to 0.04 degree using 13 bits. As seen in Figure 2 below, it combines a magnetoresistive element with an analog to digital converter and signal processing functions, fully integrated in a standard and small form factor TSSOP package.

Figure 3: TE’s KMA36 Precision KMA36 Rotational and Linear Position IC Block Diagram

In applications where precision is important, the Anisotropic Magneto Resistive (AMR) technology used by TE’s KMA36 is able to determine accurately without mechanical contact of the magnetic angle of an external magnet over a full 360° range, as well as the incremental position on a magnetic pole strip with 5 mm pole length. The sleep and low power mode, along with an automatic wake-up over I2C, make the KMA36 an excellent choice for battery based applications. Position data can be transmitted using a PWM or digital I2C communication bus for either standalone operation or microcontroller based applications. Programmable parameters provide the user with a wide range of configuration options to simplify further data processing. The KMA36 is almost insensitive to magnetic drift due to mechanical tolerances, changes in temperature or thermal stress. Its maintenance-free operation and high bandwidth make for robust implementations even in harsh industrial environments.

The TSYS01 High Resolution Temperature Sensor

In many industrial IoT processing applications, a precise temperature measurement is critical. Just a small difference in temperature of some industrial processes can mean the difference between a successful result and a failure. In some industrial processes, operator safety depends on these precise measurements, making precision and robust operation even more critical. TE’s TSYS01 is a single chip, high resolution temperature sensor. It includes a temperature sensing chip and a 24-bit Delta Sigma analog to digital converter. The combination of the digital 24-bit temperature value and the internal factory set precision calibration values creates both a highly accurate temperature reading with high measurement resolution. The TSYS01 can be interfaced to any microcontroller by an I2C or SPI interface. The microcontroller is typically used to calculate the temperature result based on the ADC values and the calibration parameters.

Connecting to the Cloud with the SD 600eval Board

Once data is collected by the sensor, you may need to further process the data, compare results to threshold targets, and transfer the data to cloud based storage for ‘big data’ analytics processing. Sensor data obtained from all the motors in an industrial factory fine, for example, can be used to predict mechanical wear and pro-actively prevent line-down events. If data is available to the motor manufacture for all motors used in all customer factories, the manufacturer can combine all this data for even more detailed analysis. Perhaps the motor manufacturer can even sell the analysis results as a service to the factory owners to help guide maintenance and repair activities. The uses of data analytics from sensors open up entirely new business models and revenue streams to companies that previously sold products only and not knowledge.

In order to connect the data collected by TE’s Sensor Board to the cloud, a processor base board is needed. To quickly prototype and prove out the design, a base board using the same 96board connectivity form factor is ideal. The Arrow SD 600eval board, shown in Figure 4 below, uses the very compact 96board standard, but it also provides significant processing power, interconnectivity options (including Wi-Fi) and noteworthy on-board memory, which is everything needed for a robust sensor processing platform with cloud connectivity.

Figure 4: SD 600eval Supports Android and Linux in a Small Form Factor- about the size of a deck of cards (Figure courtesy of Arrow) <From User Manual page 6>

The processing power of the SD 600eval is based on the popular Snapdragon processor used in a variety of cell phones and connected applications. The use of the Snapdragon quad core processor makes it possible for the SD 600eval to run Android and Linux, supporting the widest range of connectivity possible. The on board 2GB of LPDRAM and 16GB of eMMC storage makes it possible to run these operating systems efficiently. Connectivity, even in such a small form factor, is impressive with dual band 2.4 GHz and 5 Hz WLAN 802.11a/b/g/n/ac, Bluetooth 4.x + BR/EDR + BLE, and GPS available with either external or an on-board antenna. Gigabit Ethernet and SATA connectivity are also supported.

Multimedia capabilities are just as impressive with 4-lane MIPI camera serial interface (CSI), a 2-lane MIPI CSI, and 1080p HD video playback. Audio processing includes PCM/AAC+/MP3/WMA with ECNS and Audio+ post-processing. Two USB 2.0 Type A connectors (Host mode only) and one OTG USB 2.0 via Micro AB provide additional connectivity options. A 60 pin high-speed connector and a 40 pin low-speed connector make it easily expandable.

The hardware features are impressive, but the available software makes it easy to access all these hardware capabilities directly from an application program. Development is a snap when using Android or Linux and the available drivers, frameworks and Application Program Interfaces (APIs). Extensive User Guides, Board Support Packages (source and binary), boot loaders and installers give your development a very big head start.

Conclusion

If your IoT application needs a variety of sensors and a powerful IoT connected processor as well as a quick path to a working prototype, TE’s Sensor Mezzanine Board and the SD 600eval are the perfect solutions. Order the SD 600eval and the TE sensors you need from Arrow at the links provided in the reference section below. Don't delay, start today!

TE Connectivity and TE are trademarks.