The world’s appetite for electricity lifts demand by more than 70% by 2040. Despite the rising demand for electricity and energy, universal access to energy has not yet been achieved. Portable generators can fill some of the gaps in electricity landscape, providing backup or emergency power supply for residential, commercial or industrial applications when grid is unavailable or inaccessible (e.g. during recreational activities - camping, boating, etc. or other situations in which user is away from a socket).

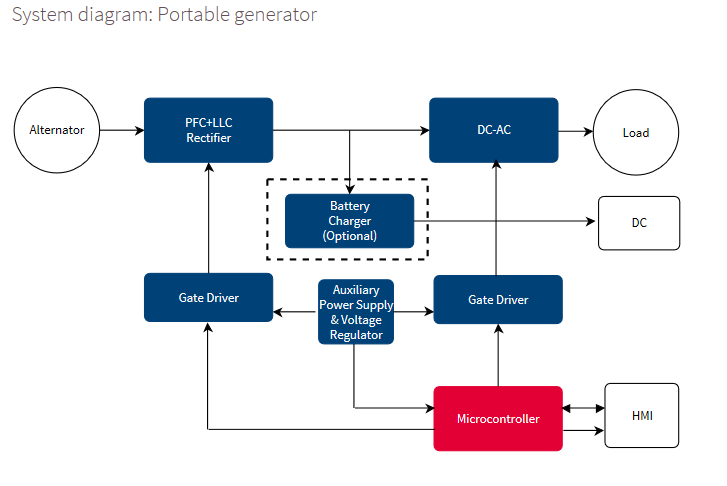

A portable generator is assembled from alternator, inverter, control panel, fuel system and battery charger. It can also have a muffler attached to its engine to reduce its operational noise.

Infineon’s broad semiconductor portfolio, provides solutions for the complete power conversion unit of your portable generator:

Inverter unit

Infineon offers a broad range of high voltage MOSFETs in various voltage and RDS(on) classes. Benchmarking SJ MOSFET technology in THD, as well as high power density SMD packages, allows for miniaturization of the inverter unit – making the portable generator solution smaller and lighter, while still meeting efficiency requirements and regulations. The highlight components for this use include 600 V CoolMOS™ C7 series for highest efficiency, 600 V, 700 V and 800 V CoolMOS™ P7 family for the perfect balance of cost and specifications as well as the 650 V CoolMOS™ CFD2 for meeting highest specifications in the inverter unit.

Highest efficiency in the inverter unit: The 600 V and 650 V CoolMOS™ C7 series from Infineon provides approximately 50% reduction in turn-off losses (E oss) compared to the CoolMOS™ CP, offering best-in-class performance in PFC (650 V C7) and LLC topologies (600V C7 series). CoolMOS™ C7 offers gains of 0.3% to 0.7% in PFC stages versus its predecessor CoolMOS™ CP. In efficiency driven applications the reduced switching losses boost efficiency and translate into lower thermal losses and lower power consumption. Ideally, the CoolMOS™ C7 efficiency is further boosted by using a package with a Kelvin source, like ThinPAK 8x8. BOM cost driven applications can use the efficiency gains for increasing the switching frequency, which allows reducing the cost of the magnetic components by up to 35%, leading to lighter and smaller portable generators.

Perfect balance of cost and performance: The latest 600 V CoolMOS™ P7 family completes the portfolio by offering the third voltage class of the P7 platform. While 700 V and 800 V series are designed for flyback, the 600 V CoolMOS™ P7 is fully optimized for hard as well as soft switching topologies, which makes it a perfect component for portable generators as they host both. 600 V CoolMOS™ P7 achieves up to 1.5% higher efficiency and 4.2°C lower MOSFET temperature versus competitor offerings, resulting from low switching and conduction losses. It secures ease-of-use and fast design-in through low ringing tendency, excellent hard commutation ruggedness and outstanding ESD protection level of HBM* (Human Body Model) class 2. In addition, it enables slim designs owing an increased power density solutions enabled by using products with smaller footprint. All three product series are designed to address typical challenges in the various applications they are desigend for by delivering best-in-class price/performance ratio with excellent ease-of-use.

Meeting highest specification requriements: CoolMOS™ CFD2 is Infineon's second generation of fast switching superjunction MOSFETs with integrated fast body diode offering improved energy efficiency and power density to secure high power conversion at competitive price. CoolMOS™ CFD2 has an ability to increase efficiency by using smaller Rg values. The implemented fast body diode provides extra safety margin for repetitive hard commutation and reduces design-in effort.

Improved efficiency and price performance: With the CoolSiC™ diode 650 V generation 5 Infineon presents a cutting-edge technology for SiC Schottky Barrier diodes, delivering greater efficiency over all load conditions at attractive cost. Devices containing the diode will also benefit from reduced EMI, increased system reliability and cost/size savings due to reduced cooling requirements. Infineon’s proprietary diffusion soldering process is now combined with a new, more compact design as well as latest advancements in thin wafer technology, resulting in improved thermal characteristics and lower figure of merit (QCx VF).

Infineon offers a comprehensive portfolio with a variety of configurations, voltage classes, isolation levels, protection features, and package options. These flexible gate driver ICs are complementary to Infineon’s MOSFETs.

Featured driver:

2EDN EiceDRIVER™ for MOSFETs are the crucial link between control ICs and powerful MOSFET switching devices. The family features two independent, non-isolated low-side channels, each capable of providing a 5 A source and sink peak current, without the need of external Schottky clamping diodes, for higher power density, lower BoM costs, cooler driver IC operation, and instant MOSFET protection under abnormal operation.

Auxiliary power supply and voltage regulator

Infineon’s linear voltage regulators are especially designed for use in harsh environments to ensure delamination-free ICs and long–term reliability. Devices hosting Infineon’s linear voltage regulators also benefit from low current consumption and pin-to-pin compatibility to industry standard parts, and are protected against load, overvoltage, reverse polarity, and overheating (overtemperature) occurrences. The regulators operate at temperature range from –40°C up to +125°C, with voltage rating up to 45 V and vert low dropout voltage. Combined, these benefits secure battery power and system space saving, excellent transient robustness, and protection at optimal cost.

Battery Management: Efficient and rugged solutions

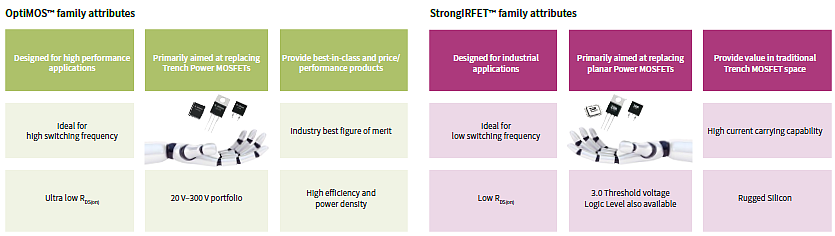

The joint portfolio of OptiMOS™ and StrongIRFET™ power MOSFETs covers 20 V up to 300 V and addresses a wide range of needs including those of battery management.

OptiMOS™ provides excellent best-in-class performance. Features include ultra low RDS(on) as well as low charge for higher switching frequencies. StrongIRFET™ is designed for rugged industrial applications and is ideal for designs with a low switching frequency as well as those that require a high current carrying capability.

Gate driver components:

Drivers are the crucial link between control ICs and powerful MOSFET switching devices. Infineon offers a comprehensive portfolio with a variety of configurations, voltage classes, isolation levels, protection features, and package options. These flexible gate driver

ICs are complementary to Infineon’s MOSFETs.

Engine management and control unit

XMC™ microcontroller family products contribute to increased energy efficiency, emission control and the reduction of BOM cost. XMC1400 is capable of controlling all aspects for efficient, flexible and low emission combustion of power generator engine e.g. EFI, ignition and choke. In addition, it can support both engine control unit/digital ignition and inverter units. Its battery load balancing feature contributes to the extended battery lifetime. With XMC1000, Infineon offers solutions for all control aspects of efficient, flexible and low emission combustion engine power generators.