Designers working in the 1U and 2U server, data storage, information and communication technology (ICT), and power supply markets know that a well-designed cooling system is key to maximizing system performance. Now, Sanyo Denki expands its line of cooling fans with three new products that feature industry-leading airflow and static pressure performance for these and similar demanding applications.

Figure 1: Sanyo Denki's new products feature industry-leading airflow and static pressure performance (source: Sanyo Denki)

All three new products are axial-flow fans using Sanyo Denki's proven Brushless DC Motor (BLDC) technology.

Axial flow fans allow high airflow at a low sound pressure level (SPL). The airflow is in a direction parallel to the axis of the impeller. They are suitable for equipment with small ventilating resistance due to low/medium mounting density.

The SanAce 40 9HV type fan offers a static pressure 40% higher than a conventional fan. With a 1U form factor, it provides effective cooling for servers, data storage systems, ICT devices, and power supplies as their power outputs rise and their densities continue to increase.

The SanAce 60 9HV type, ideal for 1.5U or 2U equipment, features a maximum static pressure approximately 92% greater than a conventional DC fan while maintaining equivalent maximum airflow performance.

Measuring 60 mm square, it's an ideal cooling solution for densely-packed equipment.

SanAce 80 9CRB type counter rotating fan features both high airflow and high static pressure. The maximum airflow is increased by approximately 22% compared to a conventional counter-rotating design while maintaining equivalent maximum static pressure.

Additionally, the San Ace 80 counter-rotating fan can maintain high static pressure at up to 50% maximum airflow, making it suitable for equipment with large ventilating resistance.

Figure 2. Axial flow fan types: single stage (a) and counter-rotating (b)

Application Requirements & Design Challenges

Why are these target markets so challenging for cooling system designers? When air is directed into an enclosed environment such as a power supply or server, a force opposing the flow of air (pressure loss) is generated due to the layout of the components and the shape of the air stream inside the equipment. This phenomenon is called ventilating resistance (also known as “system impedance” or “channel resistance”).

Air meets only slight resistance when it moves straight ahead within a wide space. When air passes through a narrow space or when the direction of an airflow changes, the ventilating resistance increases. If there is no outlet or circulation path, the ventilating resistance increases further because an airflow cannot be created.

The 1U rackmount server market is extremely competitive, with continual pressure to pack more functionality into a fixed-width slot. An ultra-dense 1U system has a full complement of power-hungry devices: multiple CPUs; up to 768Gb of DDR4 RAM; 10Gb communications; RAID controllers; plus the required support chips.

Fully-loaded, it can consume up to 1100W of power. Increasing component density increases the strain on the cooling system even if the total power remains the same, because it increases the ventilating resistance.

Key Fan Specifications

What are the key specifications to be aware of when comparing axial fans?

Maximum airflow: the maximum volume of air produced by the fan in a set period of time when the fan is operating at rated voltage. Airflow is measured in volume per unit time, e.g. m3/min or cubic feet per minute (CFM).

Maximum static pressure: The maximum static pressure obtainable when the fan is operating at rated voltage. The airflow is zero at this time. Static pressure is the power which propels air by pushing against resistance to flow occurring inside the equipment from obstructions, using the fan when air is discharged.

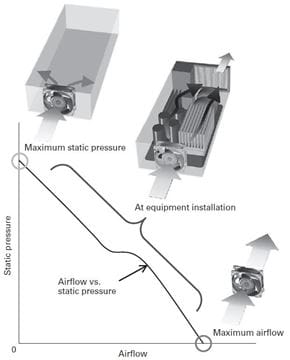

There is an inverse relationship between airflow and static pressure. A fan blowing into free space with no restrictions can deliver maximum rated airflow with no pressure loss (zero static pressure). Conversely, a fan blowing into a closed enclosure with no outlet will experience a rising static pressure; when the pressure reaches the fan's maximum static pressure rating, airflow will cease. A real-world application will have both a restricted space and an outlet so fan performance will be between these extremes.

Fans with high static pressure are suitable for the cooling of equipment with high mounting density and ventilating resistance.

Figure 3: Airflow vs. static pressure curve for an axial-flow fan (Source: Sanyo Denki)

Figure 3 shows the characteristic curve of airflow vs. static pressure (PQ curve) for a standard axial fan. Starting from maximum airflow (free air condition), any decrease in airflow from a restriction results in a gradual increase in static pressure. Axial fans have blades with airfoil cross-sections which exhibit stall characteristics similar to airplane wings. At low airflows, a phenomenon called flow separation occurs and the fan stalls, shown as a characteristic inflection at the mid-point of the curve. Airflow in the stall region is unpredictable and experiences surges, giving the multiple airflow values for a particular pressure value. The phenomenon continues until the airflow is sufficiently low for the fan blades to move air solely by centrifugal force. The static pressure then continues to increase with decreasing airflow until shutoff occurs (zero airflow).

SPL (noise): The sound level when a fan is being driven at the rated voltage. The measurement is taken in free air (ventilating resistance 0) one meter from the fan. When fans are physically assembled in equipment, the ventilating resistance cannot be zero, so noise values listed are for reference purposes. The number of blades, poor impeller balancing, obstructions close to the fan blades, and operation in the stalling range all affect the levels of noise produced by a fan.

Control method: speed control of the new Sanyo Denki San Ace fans is via a PWM input signal, allowing better optimization of fan speed, efficiency and acoustical performance. In addition, the fans have a pulse sensor output to indicate proper operation.

Expected Life: Estimating the expected lifetime of a fan is a complex process and it's important to use an industry-standard test protocol for comparison. The three new San Ace fans are rated at 40,000 hours at a 90 % confidence level running continuously at 60ºC in a free air state.

Sanyo Denki's Cooling Fan Product Family

A summary of the key specifications of the three new fans is shown in figure 4.

Figure 4: comparison of key specifications (source: Sanyo Denki)

If these fans do not suit your particular requirements, there is a large selection to choose from on our web site.

Sanyo Denki's SAN ACE family now includes AC and DC cooling fans, reversible flow fans, counter rotating fans, splash proof fans, centrifugal fans, blower fans, as well as PWM controllers.