Without exact location information, it is impossible to build autonomous cars that are safe to use in all conditions. Inertial sensors can be the voice of reason, when other sensors get confused by their surroundings.

Autonomous, driverless, self-driving, robotic, or unmanned cars – whatever you call them, they are inevitably making their way into our lives. In building these systems, safety is a key issue.

“I am sure we all want autonomous cars to be built with safety on top of priorities to keep drivers and other people in traffic unharmed. To achieve this, the vehicle needs to know exactly where it is to be able to drive and park safely,” says Tommi Vilenius, Senior Manager, Business Development, from Murata Electronics.

In autonomous driving, the demands on exact location information rise significantly. The cars need to know not just which road but which lane they are on. The margin for error is small – the widths of vehicle lanes typically vary from 2.7 to 4.6 meters.

“To build a really safe autonomous car, it needs a combination of cameras, lidars, and inertial sensors. Only then the car’s position can be estimated with high precision. And this can be achieved today!”

Cameras can get confused

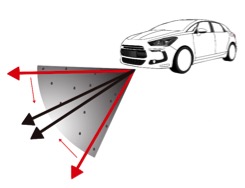

Cameras and lidars monitor and interpret the world around them with their software. However, there are situations where they can get mixed up.

“They can interpret moving ads as traffic, or high volumes of cars in an intersection can confuse the equipment, so they won’t know in which direction the car is going,” Vilenius points out.

“They also rely heavily on software, and we all know that can be problematic. Not just because software code can always have errors in it, but the ever more sophisticated software also needs more and more computing power.”

When other sensors interpret their surroundings, inertial sensor know exactly where the car is located and where it is heading in real time. Even if the cameras and lidars are confused as to which way they are moving, the inertial sensors can tell them where they are pointing.

Visual and inertial sensors can be supported by satellite-based systems, such as GPS, BeiDou or Glonass, but they only have an accuracy of a few meters, and in slow speeds, their heading information becomes poor.

Inertial sensors help keep heading information tight and the car moving in the right direction.

Get started today

The market for autonomous cars is developing rapidly, and in practice, nobody knows exactly what the next generation will bring.

“Only when we have a good number of autonomous cars on the roads will we see what needs to be improved or if something completely new is required to make traffic flow smoothly and safely. The same applies to the sensors for positioning the cars,” Vilenius points out.

However, there is no need to wait and see. Murata’s currently available sensors can be used in building autonomous cars today. Having been developed automotive applications, Murata’s inertial sensors are safe to use in autonomous cars. The company has already delivered over 50 million combined gyro sensors and accelerometers to the automotive industry.

Why choose inertial sensors?

Inertial sensor can be the voice of reason when cameras and lidars have problems with interpreting the surroundings, as they are not affected by the environment.

In autonomous cars, the most important characteristics of inertial sensors are vibration robustness and stability over temperature and vibration.

“Sensors with high stability are not fazed even if the road surface is in the worst condition. Likewise, they operate just as reliably over a large temperature range, in the hottest summer and coldest winters,” Vilenius says.

For the past two generations, Murata has already made its sensors fail-safe, i.e. should they fail, this does not lead to unsafe consequences. This is a very important feature in cars of today, but in autonomous cars it is crucial.

Murata’s sensors are also cost effective and compact.

“Murata’s sensors are simply the best on the market. They have been developed for demanding and safety-critical Electronic Stability Control applications in the automotive industry, so we know the operating environment and the requirements of the industry inside out.”

SCC2000 Series Combined Gyro Sensor and Accelerometer

Complete product platform for acceleration and angular rate detection in all three sensing axis directions; excellent bias stability, low noise level, and good vibration robustness

- • Extensive self-diagnostics features

- • −40…+125°C operating range

- • Size 12.1 x 15.0 x 4.35 mm (w x l x h)