Wireless gateway sensing and control modules with mobile application and cloud dashboard. Easy setup and installation for determining digital transformation needs.

LED, sensor and control expertise speed development when building reliable vertical farming solutions

As more vertical farming and indoor horticulture operations grow, so does the demand for products and solutions that help increase yields and consistency. Product manufacturers are meeting this demand with innovative off-the-shelf and customized offerings such as light fixtures and sensor systems.

To ensure that a design can be manufactured or integrated as smoothly as possible, there are several considerations to keep in mind. Indoor agriculture lighting and sensors have specific requirements that need expertise outside of commercial and industrial lighting designed for humans. Arrow technical specialists offer horticulture equipment design and specification expertise via the company’s robust selection of components including LEDs, power supplies, and sensors.

Arrow’s growhouse evaluation kit enables flexible deployment and scalability of a digital transformation solution

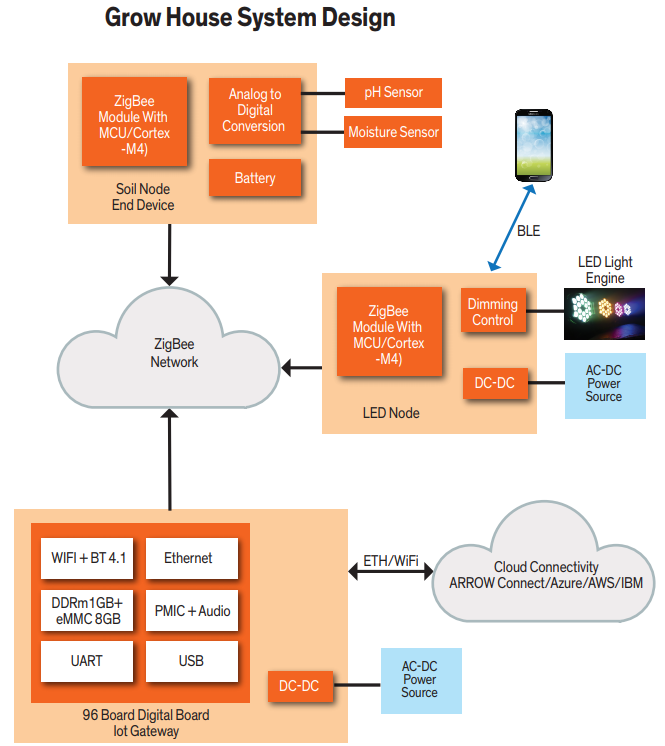

Advances in sensor and connectivity technologies along with low barrier of entry to cloud infrastructures have created cost-effective ways for vertical farming operations to take advantage of digital transformation solutions. These solutions provide benefits that go well beyond simple timer-controlled pumps, fans and lighting. To enable this transformation, Arrow is developing a Growhouse kit for sensing and controlling a digital grow house. The diagram below illustrates the components of a vertical farming digital solution available for evaluation.

The Arrow growhouse evaluation kit uses component technology available from partnerships with world-class semiconductor companies. Analog Devices solutions sense, measure, and interpret analog sensor data in the soil node. Arrow also leverages Analog Device’s technology to control the light engine, which utilizes the latest Osram Oslon Square and SSL LED’s to provide industry leading performance and efficacy while allowing for granular color control enabling the grower to produce nearly any desired spectrum. This technology provides growers with highly accurate and sensitive readings of the plant’s growing environment as well as reliable and stable control of the light engine – important attributes of a system tasked with monitoring and controlling any vertical farming operation.

Considering the size and scale of some operations, reliable and scalable connectivity is crucial. To connect these systems, the evaluation kit integrates Silicon Labs Zigbee Bluetooth modules. This allows for flexible deployment of the solution within the operation and enables the ability to scale the solution with ease. A gateway is provided to aggregate data collection for publishing to the cloud.

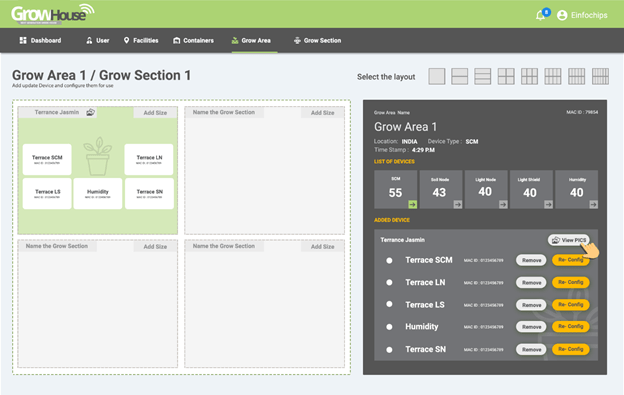

To configure, monitor and operate the system, the evaluation kit includes access to a mobile device application and cloud dashboard using Arrow Connect. In a relatively short amount of time, the user is able to configure the kit, sensors, light engine control, and cloud endpoint for monitoring the system. No firmware or application development is required to get this system operational.

The digital transformation journey can be intimidating. But, vertical farming operations that take advantage of it can run more efficiently, save time and money and create higher quality output. The Arrow growhouse evaluation kit allows the user to create the digital transformation journey that best fits their needs -- from simple light engine control to data aggregation with dashboard reporting and alarming. And when customers need advanced design engineering services, Arrow engineers are available to help integrators and growers customize a solution for their specific operation.

Arrow partnership enhances design, manufacturing, testing and logistics

Ensuring that automation functions properly requires comprehensive integration and testing capabilities that Arrow can provide. Arrow engineers have experience working with a variety of horticulture verticals. Our capabilities include engineering consulting, custom thermal design, custom spectrum design, custom cable assembly, turnkey mechanical design and custom prototyping.

Integrating technology in an indoor agriculture environment can provide powerful time-saving and yield-maximizing benefits but can also be time-consuming, with a steep learning curve requiring multiple design revisions and manufacturing delays.

Existing, well-established relationships with third-party contract manufacturing partners allow Arrow to provide fast delivery of components and turnkey products. The Arrow team continues to build expertise working with OEMs and technology integrators to deliver customized horticulture solutions that maximize the potential of well-designed LED light fixtures and panels, as well as sensors and controls with centralized communication.