Ceramic capacitors use different dielectric materials, and that leads to various capacitor types and characteristics: NP0, X5R, X7R, and Y5V. Here, while X7R is probably the most popular of these intermediate dielectric materials, it also embodies a demanding dielectric design that is very difficult to master.

Therefore, this article has picked X7R capacitors for a detailed treatment, highlighting the two fundamental aspects of their anatomy: temperature and capacitance. In X7R capacitors, also known as temperature-stable ceramics, X stands for the minimum temperature range of -55°C, while 7 denotes the maximum temperature range of up to +125°C.

And R marks the percentage of capacitance change that is permitted: +/- 15%. The capacitance change in X7R is non-linear, and it varies under the influence of electrical operating conditions such as voltage and frequency.

That, in turn, allows the X7R to cover a broad spectrum of industrial applications, where known changes in capacitance due to applied voltages are acceptable. For example, X7R capacitors facilitate over-current protection in DC-DC converters and AC-DC converters.

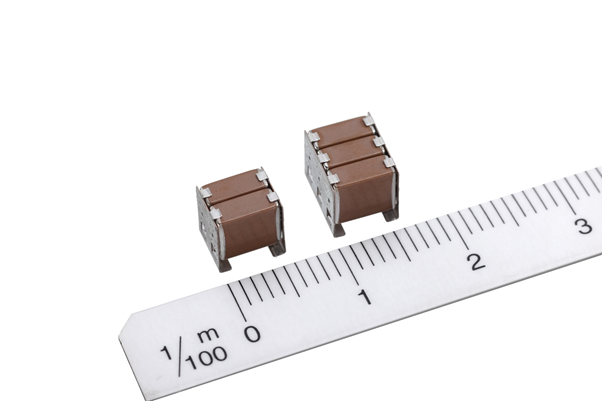

Figure 1: X7R, one of the most commonly used Class II dielectrics, serves designs requiring stability over a wide temperature range. (Image: TDK)

The X7R capacitors fall into the Class II materials as per the EIA categorization. The Class I ceramic capacitors are not sensitive to temperature changes, and that leads to high stability and lower losses. These attributes make them suitable for resonant circuit applications, but Class I capacitors typically offer lower capacitance.

On the other hand, Class II ceramic capacitors (Figure 1) are sensitive to temperature changes, but they offer higher capacitance values in smaller packages. This twilight zone of capacitance and temperature brings us to the anatomy of X7R capacitors and what matters most in establishing the capacitance value in X7R dielectric materials.

Anatomy of X7R Capacitors

For a start, it’s worth mentioning that ceramic capacitors, also termed as multi-layer ceramic capacitors (MLCCs), use ceramic materials as dielectric and metallic materials as electrodes. The alternating ceramic and metallic layers are stacked inside the capacitor package in parallel.

Figure 2: A view of how dielectric layers and internal nickel electrode layers are interlaminated in an MLCC device like X7R capacitor. (Image: Samsung Electro-Mechanics)

The multi-layer arrangement is carried out to boost capacitance in a smaller package. That also ensures the availability of MLCCs in a variety of capacitance values, voltage ratings, package sizes, and other parameters. However, this variety is intertwined with different ceramic dielectric materials which, in turn, allows these capacitors to serve a wide array of applications.

The X7R dielectric chemistry is applied to extremely thin MLCC layers with emphasis on adverse interaction of the dielectric layer and the fine nickel electrode (Figure 2). The dielectric constant is determined by the ceramic material, in this case X7R, which offers a significantly higher dielectric constant. And that can enable higher capacitance values.

Another critical aspect relating to ceramic materials is the temperature coefficient that describes the change of capacitance versus temperature. The more capacitance a material provides, the lower is the stability of capacitance over temperature.

Therefore, capacitor manufacturers choose the materials with characteristics that enable capacitors to operate within the specified variation over a specified temperature range. Take the case of X7R dielectric: capacitance can change by +/-15% across a temperature range of -55°C to 125°C.

Then, there is the voltage coefficient of capacitance, a property of ceramic materials that describes the change of capacitance against the applied voltage. The X7R capacitors have been sensitive to high-voltage signals. So, for X7R capacitors catering to high-voltage applications, it’s essential that the dielectric layer is thick enough to reduce the capacitor's internal mechanical stress.

However, the thickness of the outer layer of the dielectric, the dummy layer, can lead to the formation of cracks. Likewise, the structure of the inner electrodes can contribute to the electrostrictive effect.

Now let’s see how X7R capacitors are evolving amid the challenges confronted in moving the ceramic dielectric chemistry to higher capacitance values. The next section will also present a couple of MLCC devices and show how they are advancing the capacitance value with X7R dielectrics.

Evolution of X7R Dielectric

The X7R is a demanding dielectric when applied to extremely thin MLCC layers; especially when it comes to the interaction between the dielectric layer and the fine nickel electrode. In other words, maintaining a genuine X7R performance at higher capacitance levels is a crucial challenge.

Not surprisingly, therefore, MLCC manufacturers have mostly been focusing on easy-to-master X5R dielectrics for capacitance values of up to 100 µF and beyond. On the other hand, the number of X7R suppliers who have managed to develop high-capacitance MLCCs is quite limited.

Samsung Electro-Mechanics, for instance, is one of the few MLCC vendors that have invested top R&D dollars in advancing the capacitance value in X7R dielectrics to 47 µF. The Korean component supplier is also driving the miniaturization in MLCCs to enable their use in small form-factor designs.

The CL05B104KO5NNNC capacitor is a 100 nF surface-mount capacitor which is targeted at portable and miniature applications using batteries and devices operating off USB power. This MLCC from Samsung facilitates decoupling, filter and bypass operations.

The ceramic capacitor can withstand 16V DC and comes in a 0402 package that measures 1 mm x 0.5 mm x 0.5 mm. That allows the X7R capacitor to significantly ease the PCB mounting and shrink the board real estate. The CL05B104KO5NNNC capacitor is also fully compliant with the RoHS standard.

Another prominent capacitor supplier for compact surface-mount footprints is Kemet. Its X7R capacitors are facilitating higher voltages in automotive applications such as lighting, sensors, and electric charging. Kemet is also shrinking the MLCC footprints while its X7R dielectrics support higher voltage ratings.

Figure 3: Kemet’s ceramic chip capacitor is available in capacitance values ranging from 10 pF to 47 µF. (Image: Kemet Corp.)

Take, for instance, Kemet’s C0603C104K5RACTU ceramic capacitor that comes in a 0603 package size and offers capacitance value of up to 100 nF. It features a minimal change in capacitance relating to the ambient temperature. That makes C0603C104K5RACTU (Figure 3) highly suitable for applications such as bypass, decoupling, filtering and transient voltage suppression (TVS).

The X7R capacitor can also be employed in frequency discriminating circuits where the quantity of charge (Q) and stability of capacitance characteristics are not critical. That’s because this ceramic dielectric capacitor from Kemet exhibits a predictable change in capacitance relating to time and voltage.

X7R: New Design Frontiers

As shown in the above design examples, the X7R capacitors are quickly evolving to better serve the smoothing and decoupling applications in industrial designs. The greater stability in X7R dielectrics also means that they can now cater to resonant circuits in wireless and plug-in charging systems.

Furthermore, the X7R capacitor suppliers are now providing tools that allow engineers to plot capacitance variations in different design environments. Designers can also carefully review various capacitor sizes and voltage ratings.

In capacitors like X7R, classified with high dielectric constant, the actual capacitance value may differ from the nominal value when the voltage is applied. Therefore, if this information is not available in the datasheet, make sure you check this out with the MLCC vendor.