Choosing connectors requires both attention to detail and an understanding of the many ordering parameters involved. Circular connector part numbers, for example, can consist of over thirty characters, all of which represent different configuration specifications.

Connector shell configuration parameters refer to how a connector is manufactured and how it will work in your design. We'll examine the variety of shell, hood, and backshell parameters found in connector part number configurators.

Connector Backshell Types

When building a connector shell, the first parameter to consider is the type of backshell you need. The shell that a connector utilizes is driven by the connector's environment and use case. For example, connectors in naval control systems require humidity, water, and dust specifications, while shells used in aerospace applications may require radiation hardening and weight-limiting construction. Shell 'type' nomenclature varies across manufacturers, so be sure to reference a datasheet within your desired connector category and manufacturer to understand what various connector types are available.

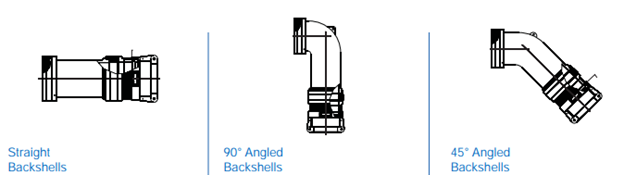

Backshell Angle Options

Nearly all connector backshells―regardless of connector type, category, or manufacturer―come in at least three angle options. The backshell angle relates to how the conductor mates with its partnering connector, as shown in the image below. Varying connector backshell angles allow proper cable routing in confined spaces and generally come in straight (0°), 45°, and 90° varieties.

Image: Amphenol

Coupling the Connector & Backshell

Common in the circular connector world, couplers connect the backshell to the actual connector and enable varying degrees of rigidity between the connector and the backshell. For example, connectors in high-vibration environments may require the use of a self-locking coupler to prevent the connector from accidentally decoupling. If accidental decoupling is not a concern, a simpler direct coupling allows the connector to thread to the backshell directly.

Backshell Materials & Finishes: MIL-SPEC Backshells & More

The materials and finishes used on backshells must meet guiding standards and requirements, as such as:

- AMS

- ASTM

- MIL-SPEC

Some commonly used, corrosion-resistant materials are aluminum alloy, stainless steel, elastomers, and NiAl-Bronze.

Strain Relief for Connectors

Connector strain reliefs avoid unwanted disconnection by removing the force exerted by the cable assembly onto the conductor assembly. Most strain relief devices are clamp assemblies that integrate with the backshell. These devices clamp onto the sheath of the cable and rely on friction to prevent the cable from moving. Clamps may be self-locking or not, and they vary drastically in size relative to the cable size. Strain reliefs can be integrated into the connector shell directly, or selected in addition to the connector backshell, which means that backshell strain reliefs might have a different part number entirely.

Backshell Mounting Type

The shell's mounting style is usually related to its intended use. Common mounting styles include:

- Wall mounted

- Line/in-line

- Box mounted

- Surface-mount

- Straight plug

- Lanyard release plug

- Solder mount

- Flange mounted

- Jam nut receptacles

Some manufacturers also carry additional, application-specific mounting styles. You can find connector mounting types across nearly all connector families that require backshell configurations.

For more information on ordering circular connector ordering information, top circular connector manufacturers, or to shop all connector categories, visit Arrow.com.