Manufacturers in all industries know the key to better productivity is keeping the production equipment running smoothly without unexpected stops. Short stoppages often do occur, however, and longer downtime for repair or part replacement remains a risk.

Manufacturers in all industries know the key to better productivity is keeping the production equipment running smoothly without unexpected stops. Short stoppages often do occur, however, and longer downtime for repair or part replacement remains a risk.

To improve factory productivity, people tend to focus on enhancing the processing capacity of the equipment itself. But all those short stoppages and sudden shutdowns are actually more inconvenient. They make it hard to predict productivity, and it's bothersome to deal with them. Potential breakthroughs in this area would be a key advantage of smart factories.

To keep production lines running safely and as productively as planned, inspection and maintenance are essential (Fig. 1). There's no denying that this also takes time, effort, money, and people, yet some countries have faced a shortage of maintenance personnel in recent years amid a declining birth rate and aging population. Also, as maintenance is linked to product value indirectly, many companies would prefer to reduce the personnel involved.

Fig. 1: Streamlining inspection and maintenance may be a key advantage of smart factories

Production lines may stop for a variety of reasons, but short stoppages occur when various factors add up – slight delays along the line, or equipment malfunctioning or going slightly out of sync. This multiplicity of factors makes short stoppages difficult to predict.

Recently, manufacturers have applied IoT to collect data on equipment operating conditions and worker movement, which can be understood in real time. Collection and big-data analysis of the data acquired has led to techniques for predicting short stoppages by referring to past instances. Anticipated short stoppages may be preventable by adjusting the operating conditions of relevant equipment or having more workers involved.

By contrast, other factors may require repair, if mechanical parts wear out or rust, dirt or foreign matter becomes stuck, or warmer temperatures cause expansion. Changes that ultimately lead to failure are complex and happen gradually, which makes this failure hard to predict.

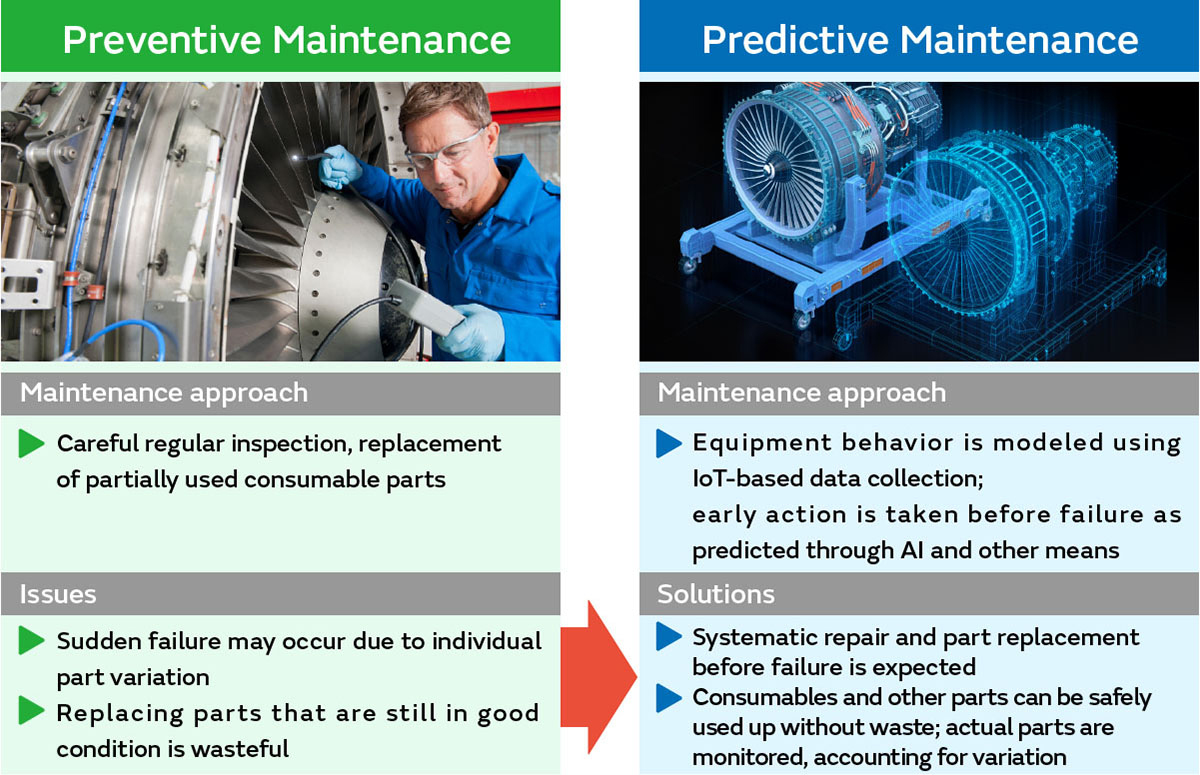

Preventive maintenance has traditionally involved careful regular inspection and replacement of partially used consumable parts to avoid failure that requires repair. This approach has presented two challenges. First, individual part variation means that failure may occur sooner than expected. Second, it seems wasteful to replace perfectly good parts before the end of their useful life. But in recent years, IoT and AI have enabled a more proactive stance through early detection of signs of failure. This is known as predictive maintenance (Fig. 2). Potential indicators such as appearance, sound, pressure, heat, and vibration are collected as data from sensors on production equipment, and analysis techniques that include AI help detect signs of failure or malfunction in advance. With predictive maintenance, consumable parts can be used to their full potential. This enables a systematic approach to maintenance and part orders.

Fig. 2: Difference between preventive and predictive maintenance

At some long-established factories, seasoned engineers can sense equipment anomalies by sound, or by vibrations felt with their hands. This keen awareness has prevented short stoppages or equipment failure requiring repair.

There are fewer and fewer of these veteran engineers now, and as the birth rate declines in a graying society, it is hard to pass on these skills and fewer people to train. With smart factories, systems can be built for nonstop monitoring of all production equipment without missing anomalies – a feat impossible to match conventionally at factories that rely on the skills of a few people.

Failure prediction is not the only benefit of more advanced data collection and analysis technologies with more accurate anomaly detection. We can also predict issues such as declining yield and quality. However, more accurate anomaly detection requires manufacturers to collect enough high-quality data from suitable areas, which also calls for more advanced sensors, communication modules, batteries, and other components of IoT systems that collect the data (Fig. 3).

Fig. 3: Key components for higher anomaly detection accuracy in smart factories

To this end, these components must be made smaller, lighter, and more energy-efficient, so that installation requirements do not limit where data can be collected. The components must also have high environmental resistance and noise immunity to ensure stable operation even under tough factory conditions.

One development in recent years that is gradually becoming more popular as a power source for IoT devices is energy harvesting, which turns ambient energy sources such as light, temperature differentials, electromagnetic waves, or vibration into electric power. Looking ahead, oxide-based solid-state batteries that improve the environmental resistance of battery-powered IoT devices promise to expand the areas where these devices are used.

Featured Product

参阅相关产品

参阅相关产品

Smart factory Sensors, wireless communication module, batteries

MEMS Sensor- SCA3300 Accelerometers Micro Batteries – CR series CR2032R

Wireless Communication Module – LoRaWAN Modules LBAA0QB1SJ