In both home and industrial wiring, it’s necessary to stick stranded cables into screw terminals or spring connectors. For industrial equipment, hundreds, or even thousands of these connections may be required to automate a task. If just one of these wires comes loose or breaks, you're most likely in for a bit of costly downtime.

Each connection is therefore critical. While the flexibility of stranded wire allows for much easier routing than can be expected from solid-core wire, the ends tend to splay apart. This makes the actual connection to a screw or spring connector a bit of a dicey proposition. In a perfect world, you’d have wire that’s stranded in the middle, and solid on the ends.

Sound like an impossible task? It’s actually possible and easy to implement with the use of ferrule connectors.

What is a Ferrule?

Broadly speaking, ferrules are any sort of ring used to either reinforce a shaft or bind together strands of a material. In the context of wiring, a ferrule is a small deformable metal tube, generally made out of tin plated copper. This short tube (or long ring) is placed over a section of stranded wire extending from stripped insulation, then compressed with a crimping tool to hold the strands together. Ferrules discussed here also feature a flared portion on one end, which serves to guide the strands into the main crimped section and provide strain relief.

What Does a Ferrule Do?

Once crimped, the bundle is transformed into what, for practical purposes, acts as the end of a solid-core wire. The addition of the ferrule presents several advantages, including the aforementioned strain relief and the fact that every strand of a wire can now be inserted into a connector, without the fear of a few being displaced to the sides upon insertion. Ferrules greatly reduce the contact resistance between the wire and connector, and even help cut down on the oxidation in the strands because of the lack of air space between them.

Wire Ferrule Color Coding

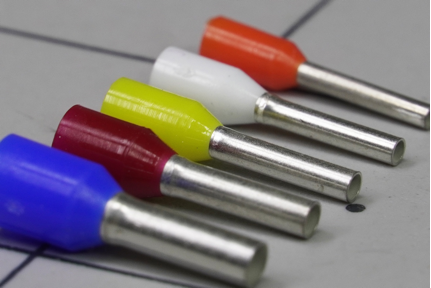

Ferrules come in a wide variety of different sizes, depending on the wire that you need to crimp, with color codes on the shoulder portion that indicate the size. One possible issue here is that there are at least three different ferrule color codes, which can lead to confusion if different types are mixed. Ideally, you would keep ferrules in the container they came in until used, such the ferrule kit in the above image, removing any doubt about what you’re using.

Use in the US?

While the use of ferrules is required in Europe for electrical equipment to receive a CE marking, ferrule usage is not required in the US. That being said, it’s possible to find high quality US-built machinery where these connectors are applied. If you’re buying equipment, it can be a good idea to look for this wiring technique in devices under consideration, or to specify it in machine requirements. Such forethought can potentially save many maintenance headaches in the future, along with the corresponding downtime.

Mandatory or not, using ferrules is good electrical practice. Whether you’re building something for a customer, specifying a device for your company, or building equipment in-house, ferrules should be a part of the conversation.

As another option for securely fastening a wide variety of stranded or solid-core wires, with ferrules or without, see this article about the amazingly versatile Wago lever nut connectors.