Current control is the key to improving the operational efficiency of the motor. How to accurately measure the intensity of the current requires an accurate current sensor. The current sensor using TMR technology will be one of the best choices for related applications. This article will show you the characteristics of TMR technology, the types of current sensors, and the product characteristics of Crocus Technology TMR current sensors sold by Murata to provide your reference in selecting products.

TMR technology can achieve high magnetic sensitivity and stable performance

TMR (Tunnel Magneto-resistance) refers to a magneto-resistance effect that occurs in a magnetic tunnel junction (MTJ). MTJ is composed of two electrically-conducting magnetic layers located on both sides of a thin (nanometer-scale) but highly robust insulating layer. One magnetic layer has a fixed magnetic moment direction, while the other layer can be freely changed to follow the direction of the local magnetic field. In the case of a thin insulating layer, electrons can be tunneled from one ferromagnet to the other side, and its tunneling resistance changes with the relative direction of the ferromagnetic materials on both sides. The magneto-resistance effect is the scientific basis of magneto-resistance random access memory (MRAM) and magnetic read-write heads in hard disks, and is also used in the field of sensing.

Sensors employing TMR technology sometimes have the same purpose as Hall effect sensors. Still, since TMR is based on different physical phenomena, it works completely differently, which explains their superior characteristics as magnetic sensors. The magneto-resistance effect is the characteristic of the device changing its resistance value under the influence of an external magnetic field, so it can be used for various magnetic fields in various applications.

Crocus Technology developed and is patented for its innovative XtremeSense® TMR technology to provide excellent magnetic induction performance for many applications. XtremeSense® TMR technology can achieve high magnetic sensitivity, stable performance in the temperature range, low noise and low power consumption, making it useful in various end products and markets.

Current sensors can detect the current for further analysis and control

he current sensor is a device that can detect the current in the wire and generate a signal proportional to the current. The generated signal can be an analog or digital voltage or current signal. These signals can be connected to a meter (e.g. an ammeter) display and stored in a data acquisition system for further analysis or control.

The current and output signals sensed by the current sensor can be output in analog or bipolar when the alternating current (AC) is input. It can replicate the waveform of the sensed current, or it can be output in unipolar, which is proportional to the average value or RMS value of the detected current. In the case of direct current (DC) input, the unipolar output can replicate the waveform of the induced current, or digital output is used. The unipolar output and digital output which switches when the sensed current exceeds a certain threshold.

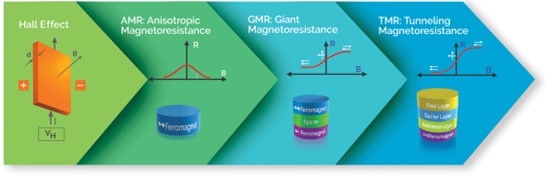

Current measurement can be classified according to basic physical principles, such as Faraday's law of induction, magnetic field sensor, Faraday effect, Hall effect sensor, transformer or current clamp meter, fluxgate sensor, shunt resistor, fiber optical current sensor, Rogowski coil, magneto-resistance (MR), etc. The TMR introduced in this article belongs to MR technology. In addition to TMR, MR-based sensors also include anisotropic magneto-resistance (AMR), giant magneto-resistance (GMR), giant magneto-impedance (GMI) and other technologies. These magnetic field sensors are suitable for the detection of AC and DC currents, and their accuracy is higher than Hall Effect, thus they have been widely adopted in the industry.

High precision sensor with low power consumption and high sensitivity

The magnetic sensor products introduced by Crocus are based on its innovative patented XtremeSense® TMR technology, using monolithic technology to enable the magnetic sensor to be fully integrated into the proprietary CMOS lithography process, thereby simplifying the manufacturing process, achieving a higher level of integration and performance indicators, and achieving high sensitivity, low noise and stable performance within a wide temperature range.

These magnetic sensors not only have high magnetic sensing performance, but also have the advantages of reliability, small footprint, current and thermal isolation, high frequency operation and low power consumption. They have high sensitivity, low noise and low power consumption at the nanometer-scale. They also provide high reliability and stable magnetic properties in the temperature range, and can also provide excellent stability in extreme operating environments. These characteristics make it ideal for many different operating environments and applications that are important for accuracy and rapid response. It is an ideal sensing solution for the Internet of Things and industrial applications. It is widely used in motor/motion control, energy management systems, inverters, battery management, charge management and many other applications.

The TMR sensors introduced by Crocus include current sensors (contact, contactless) and position sensors (switch, 1D, 2D). The contact current sensor introduced in this article is a high resolution, high bandwidth and fully integrated sensor, which is a solution for products such as solar power generation system, battery management system, server power distribution unit (PDU), motors, refrigerators, laptops and security components.

High precision isolated TMR current sensor

CT43x XtremeSense® TMR sensor introduced by Crocus is a 1 MHz bandwidth, high accuracy isolated current sensor with an overcurrent fault detection function. CT430(VCC = 5.0V) and CT431 (VCC = 3.3V) are high bandwidth and ultra-low noise integrated contact current sensors, using Crocus Technology’s patented XtremeSense® TMR technology, providing high accuracy current measurement for many consumers, enterprises and industrial applications. The sensor supports eight current ranges, where the integrated current-carrying conductor (CCC) will handle currents up to 65 A and generate current measurements as linear analog output voltages. It achieves a total output error of less than ±1.0% full scale (FS) in the voltage and entire temperature range (-40℃ to +125℃).

CT43x XtremeSense® TMR sensor has 1 MHz bandwidth and 300ns fast response, and current consumption is about 6.0 mA. CT430 has 9.0 mARMS, CT431 has ultra-low noise and high signal-to-noise ratio (SNR) with 9.5 mARMS, and both have integrated common mode field suppression of -54 dB to ensure that stray field will not affect measurement in working applications. CT43x offers an integrated over-current detection (OCD) circuitry to identify out-of-range currents (OCD) with the result outputted to the fault pin (FLT#). The FLT# is an open drain, an active LOW digital signal that the CT43x activates to alert the microcontroller that a fault condition has occurred. CT43x is packaged in an industry standard 16-pin SOIC-Wide and is certified by UL/IEC 62387, UL1577 and IEC 61000-4-5. It is "green" and RoHS compliant. CT43x can be widely used in motor control, PLC/control panel, solar/power inverter, outdoor products, UPS, SMPS and telecom power supply, battery management systems, smart appliances, smart electric meter, residential/commercial HVAC, industrial appliances, power supply, overcurrent fault protection and other fields.

Conclusion

Current sensors have a wide range of applications and play a key role in the efficiency of motor operation. The Crocus TMR current sensor introduced in this article has high bandwidth, ultra-low noise and high accuracy characteristics. It will be one of the best choices for motor control and various consumer and industrial applications.