Battery failures have become a dominant story in tech news recently. The Samsung Galaxy Note 7 has now been through 2 recalls and is being pulled from production, effectively killing the entire product. When all's said and done, the damage to Samsung could be above $5B, and that doesn’t take into account brand damage.

People will probably forgive or forget these battery failures, but in electronics design we should always seek to remain vigilant as we add these volatile parts to our systems. In this article, we will go over some of the reasons batteries fail, how they fail, and some guesses as to the root of Samsung’s problems in the Note 7.

With our world becoming more mobile, batteries are present in just about everything. The incredible power density of lithium-ion cells has enabled a lot of what we consider essential to modern life. Many promising alternatives crop up from time to time in various university labs, and while they are really cool, almost none of them see their way through to production in a reasonable volume, so I don’t think lithium is going away anytime soon. Also, this is not the first time lithium-ion cells have been the subject of interesting failures or massive recalls; HP and Sony just recalled battery packs in June 2016, Sony recalled 9.6 million cells in 2006, Lenovo in 2014, and Fujitsu in 2015. The point of this list is that batteries have had problems before, but taking the risk of these problems has been worth the potential issues. When properly designed with complete protections and strong quality control at manufacturing, there are relatively few issues with lithium-ion battery cells, but when they do choose to fail it can be a quiet whimper or an extreme bang.

What Causes a Battery to Die?

So why do batteries fail? It is all about the stress the battery cells are placed under by electrical items such as current or voltage and external influences such as temperature or physical impacts. The stress factors are not as big of an issue if there is an inherent flaw in the cell from manufacturing, but we will look past that for the purpose of this article.

● Over Voltage

○ Charge voltage above the recommended cell range results in Lithium Plating, which reduces capacity and causes overheating

● Under-voltage/Over-discharge

○ Discharging below the recommended cell voltage will break down the anode, resulting in increased self-discharge and potential short circuits

○ Extreme over-discharge will flat out kill the cell, rendering it useless

● Low temp

○ Reduced power output and Lithium plating, resulting in capacity loss

● High temp

○ Unless heat can leave fast enough, thermal runaway and cell destruction will result

○ A fuse cuts the current flow if the skin temperature of the cell approaches 90°C (194°F). (Only if present in the design)

● Thermal Runaway

○ Solid Electrolyte Interface layer breakdown at 80°C

○ Hydrocarbon gas release at 110°C or as low as 70°C

■ Pressure build up that has to be vented or there will be rapid disassembly

○ Separator breakdown at 135°C

■ Short-circuit between electrodes

○ Electrolyte breakdown leads to cathode releasing oxygen at 200°C

■ Highly exothermic with extreme temperatures and pressures

● Over-current during charge or discharge

○ Cell temp increases

Why Do Lithium-Ion Batteries Die?

Lithium-Ion batteries are fickle devices and can fail under many circumstances. Depending on the reason for their failure, the batteries can go quietly into a dead state or they can go out in a blaze. Usually when a cell dies due to Over-Discharge or Low Temp Operation, they go quietly and just stop accepting charge or have less capacity than is needed for the system they were designed into. Should a cell become a victim of a high temperature failure from over-current situations like a short circuit or just extreme environmental temperatures, they will usually fail in a more extreme manner. If the cell was designed with a vent and proper temperature shutdowns, then it will likely get hot and vent.

A “puffed” battery is pretty common in the Remote Control vehicle community and is a sure sign that your battery is no longer safe to use, as it has experienced increased internal pressure from gas. If the reaction is faster than the vent can handle or there is no vent, the cell will start to expand and eventually explode. Depending on the temperatures that the cell reaches, some parts may catch on fire, especially since the cathode breaking down results in 200°C+ temperatures. To put that temperature in perspective, paper ignites at 233°C.

Samsung Galaxy Note 7 Battery Problems

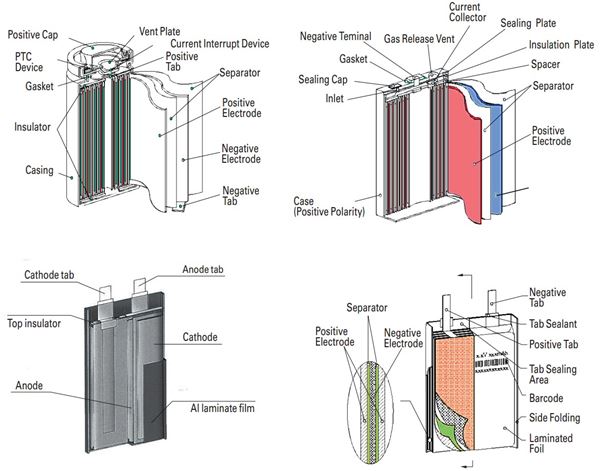

Ok, we’ve looked at the batteries and how they can be difficult, but why do we think the Note 7 is having such an issue with its batteries? Two factors have come to light that could explain some of the problems. The initial battery cells from Samsung’s own battery group were oversized and had to be squeezed into the Note 7 shell. In my conversations with some suppliers who have deeper knowledge of the circuits inside the phone, I have been told that the phone had protections for Over-voltage, Over-Current, and Over-Discharge, but they neglected to include thermal protection like a thermal fuse or PTC thermistor connected to their charging system. The TI BQ25898 that was used to handle the battery has an input for battery temperature monitoring, but if a thermistor, like Vishay's featured below, is not hooked up, then it cannot determine what is happening to shut down the battery.

Visualizza prodotti correlati

Visualizza prodotti correlati

How does compression result in failed batteries? Compression affects Lithium-Ion pouch cells in two ways. The compression results in a higher cell voltage and, more importantly, separator creep according to research out of Princeton University. Higher cell voltage would have stressed circuits and resulted in more battery heating, but I don’t think that is a complete explanation. The separator creep is a much more interesting piece of information since the separator is what keeps the battery from short-circuiting internally. Should this separator fail, the battery would likely fall into a thermal runaway situation and catch fire or explode. This line of thought has traction due to Samsung’s own statement from their UK website that, “Based on our investigation, we learned that there was an issue with the battery cell. An overheating of the battery cell occurred when the anode-to-cathode came into contact which is a very rare manufacturing process error.” I emphasized the part of the statement that lends support to a separator issue. Samsung thinks it is part of a manufacturing error, which it may be, but I think it is an engineering failure involving an attempt to squeeze too large of a cell into too small of a space and failure to provide every protection possible.

A big reason why I think this is an engineering failure and not just a manufacturing failure is the lack of thermal protection. Proper protection could potentially have reduced the number of incidents by shutting down batteries that were on their way to thermal runaway. This protection could have been achieved by including something like the MHP-TA series from Littelfuse, which houses a PTC and a bimetallic circuit breaker. If the separator was already breached, the thermal protection wouldn’t have helped, but hopefully it would have prevented many batteries from getting to that point.

So there you have it. Lithium-ion batteries are volatile. When working with lithium based cells, you must pay the utmost attention to every aspect of safety and protection or risk major issues. Thankfully it seems like the Note 7 issue has not yet caused loss of life or extreme property damage (potentially one car burned), so for as bad as this entire incident may seem for Samsung, it could have been much worse.