High thermal performance with TRENCHSTOP™ Advanced Isolation

Abstract

Power components mounted on a system heatsink usually need to be electrically isolated. Traditional solutions for electrical isolation on TO packages, such as thermal grease, tend to be difficult to handle in volume production, and expensive. FullPAK packages offer simpler assembly requirements, but have a high thermal resistance from chip-to-system heatsink. The new TRENCHSTOP™ Advanced Isolation from Infineon is a fully insulated package solution that does not require thermal isolation pads or thermal grease due to an effective and reliable thermal path from the IGBT die to the heatsink. The new package offers increased power density, improves reliability, and reduces system and manufacturing costs. This new package has a measurably lower thermal resistance in the system compared to both standard TO-247 and TO-247 FullPAK assemblies.

1. Introduction

Molded packages are commonly used as housing for power electronic components. These components are mounted on an external heatsink to improve the thermal performance of the device. Usually, several power components with different electrical potentials are mounted on a common heatsink. Each device must be electrically isolated from the others, and from the heatsink itself.

To achieve electrical isolation, commonly used packages like a standard TO-247 must have an insulating layer or material between the exposed lead frame and the heatsink. Mica and silicone pads are well-known insulating materials, and are usually assembled with thermal grease. This solution requires careful alignment during assembly, can be messy, and the thermal grease dries over time, making it less effective and efficient. Another common solution is a fully insulated package where the device is fully encapsulated with a molding compound. A fully insulated package is easier to handle in production than the leadframe option because extra insulating material is not required. Unfortunately, fully insulated packages have a high thermal resistance from chip-to-system heatsink, limiting their output power capability.

Compared to a FullPAK, devices in the TRENCHSTOP™ Advanced Isolation package do not require additional insulating material and thermal grease. The major advantage of an Advanced Isolation over a FullPAK is the low thermal resistance from chip to heatsink. The output power limits that FullPAKs experience are no longer a factor with Advanced Isolation, and devices can operate at their full-power capability. This new package has long-term thermal conductivity and insulation reliability according to industrial standards. [1]

2. TRENCHSTOP™ Advanced Isolation package

The Advanced Isolation package is part of a fully isolated package family. It has a high thermal conductivity layer with excellent electrical insulating properties. This Advanced Isolation layer encapsulates the copper thermal pad on devices with an exposed leadframe such as the standard TO-247-3. Figure 1 shows top and bottom sides of the Advanced Isolation package in a TO-247-3 TRENCHSTOP™. This package has been designed to be compatible to the TO-247-3 in form and fit.

Figure 1 - Top side and bottom side of the TO-247-3 TRENCHSTOP™ Advanced Isolation package

The device bottom side includes the highly thermally conductive insulation layer. This layer reduces the thermal resistance from junction to heatsink by about 50 percent compared to a TO-247-3 FullPAK or a TO-3P FullPAK. No additional thermal grease is required to achieve this performance.

The Advanced Isolation package is identified within Infineon’s IGBT and Diode nomenclature by the letter “F” at the third position, e.g. IKFW40N60DH3E. It is available in two versions: the price/performance and the best-in-class. The price/performance version is identified with the letter “E” at the last position within Infineon’s IGBT and Diode nomenclature, e.g. IKFW40N60DH3E. This version is a suitable replacement for FullPAKs or TO-247-3 isolated by an average-performance insulator foil. This refers to a standard polyimide-based reinforced carrier insulator foil with 152 µm thickness and a thermal conductivity of 0.9 W/(mK). The best-in-class version is a replacement for TO-247-3 isolated by a high-performance insulator, like a polyimide-based reinforced carrier insulator foil with 152 µm thickness and a thermal conductivity of 1.3 W/(mK).

2.1 High thermal conductivity

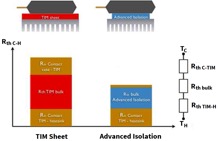

The improved thermal performance of the Advanced Isolation package is attained by eliminating almost all of the contact resistance Rth,C-TIM between the package die pad and isolation. Figure 2 shows the comparison between traditional thermal interface material (TIM) sheets and Advanced Isolation. The thermal resistance of the bulk material Rth,bulk for the Advanced Isolation is also significantly lower than the TIM. Both contact resistances case-TIM and TIM-heatsink become more relevant with improved thermal conductivity of the bulk material.

Figure 2 Thermal resistance case-heatsink RthCH contribution for the TIM sheet and the Advanced Isolation package concept

2.2 Advanced isolation package reliability

Packages with Advanced Isolation are fully isolated with a dielectric withstand capability that exceeds 2.5 kVrms per 60 seconds. The long-term performance and reliability of the package has been tested, and performs according to JEDEC Standard JESD22. These tests include passive temperature cycling, and high temperature and high humidity storage with 1.4 kV applied between the package die-pad and application heatsink. The mechanical and electrical properties remain unchanged in combination with moisture storage and temperature cycles. Table 1 summarizes the Advance Isolation package reliability qualification tests. The package has passed environmental testing for mixed gas corrosive atmosphere according to IEC 60068-2-60: 2015-06 and tests related to connector insulation resistance at high voltage, according to IEC 60512-4-1: 2003-05.

2.3 Assembly of Advanced Isolation Package

The Advanced Isolation package can be assembled directly onto a heatsink using either a clip or a screw [2]. The insulation layer of the package is not intended to be used as a last insulation barrier, and the device must not to be used without being previously assembled on a proper heatsink [3]. Avoid improper use of the clamping systems, vibration tools, fixing elements for assembly, and terminal bending, because this may lead to scratches, cuts or other damage to the insulation layer. If the device is correctly assembled to a heatsink, devices with Advanced Isolation packages do not require any additional external insulating materials or thermal grease. This feature can dramatically simplify the assembly of the device when compared to other isolated discrete devices, like FullPAKs and IsoPACKTM, or TO-247-3 with external isolation foil.3. Thermal measurements and comparison

To assess the higher performance of packages with Advanced Isolation, thermal measurements and electrical tests have been performed on complete power systems. In the first test TO-247-3 with Advanced Isolation is compared to TO-247-3 with a TIM sheet. The second test compares TO-247-3 with Advanced Isolation to FullPAK. All tests are done with the same heatsink sizes and with identical mounting force on the device under test.

3.1 TO-247-3 Advanced Isolation and TO-247-3 with TIM-sheets

The performance of a best-in-class Advanced Isolation IGBT rated at 50 A is compared to an IKW50N60H3 having the same die size, with an isolation foil between the leadframe and the heatsink. The configuration within the test is a 2200 W half-bridge AC output converter. The isolation foils used are commercially available polyimide-based reinforced carrier insulators with 152 µm thickness and 1.3 W/(mK) thermal conductivity, which is considered high-grade isolation material. The gate resistor values were chosen to limit the IGBT’s overvoltage peak safely below 600 V, and the same values were used for all tests [4]. Figure 3 shows that the case temperature of the best-in-class version is at par with the IKW50N60H3 with a higher grade isolation material.

Figure 3 - Thermal measurements between the best-in-class version vs. a TO-247-3 HighSpeed 3 with a higher grade isolation material in a half-bridge AC output converter

The thermal performance of the Advance Isolation package is achieved without thermal interface material and thermal grease.

3.2 TO-247-3 Advanced Isolation and TO-247-3 FullPAK

The thermal performance of a 40 A rated IGBT in Advanced Isolation package is compared to a 40 A IGBT in FullPAK on a power factor correction (PFC) board. The Advanced Isolation package used for this comparison is the price/performance version, which is a suitable replacement for FullPAKs. The PFC test board operates at 22 kHz switching frequency with 230 VAC input and 400 VDC output. The same gate resistor value is maintained during all tests, chosen to limit the IGBT’s overvoltage peak safely below the rated collector-emitter breakdown voltage. Figure 4 displays the thermal measurements showing that the FullPAK case temperature is higher compared to the Advanced Isolation package by 11°C at 2500 W output power.

Figure 4 - Thermal measurements between the TO-247-3 Advanced Isolation price/performance version vs. a TO-247-3 FullPAK in a PFC test board

4. Conclusion

The Advanced Isolation package achieves electrical isolation between power components and the system heatsink without the need of a thermal interface material and thermal grease. The high thermal conductivity of the package provides a thermal performance that is on par with a solution that uses high-grade isolation materials plus thermal grease, and better than a FullPAK. The Advanced Isolation package from Infineon is a breakthrough solution for discrete power devices.

Visualizza prodotti correlati

Visualizza prodotti correlati

Visualizza prodotti correlati

Visualizza prodotti correlati