Electric vehicles (EVs) have become the most important direction of development in the automotive industry. How to safely speed up the charging of EVs has also become one of the factors that will decide whether EVs can be widely accepted and purchased by people around the world. This article will show you the key issues of EV charging and the power filter solutions introduced by SCHURTER for fast charging stations.

Protection against overcurrent and overheating to improve the safety of fast charging

As a result of stricter air pollution regulations, more and more cities are hoping to impose a driving ban on diesel vehicles. The automobile industry is under increasing pressure to provide the lowest possible emissions of vehicles, and EVs have become an important development direction for automobile manufacturers. However, to persuade buyers to buy EVs, it is important to emphasize with simple slogans that the latest EVs can be zero-charged to 100% in a few minutes and can travel hundreds of kilometers. EV manufacturers must also compete with each other for ever shorter charging times and longer ranges.

The time required for charging is simply calculated by dividing the vehicle's battery capacity (kWh) by the charging station's power (kW), so that you can get the hours of being fully charged (0-100%), but it is not that simple in fact.

The charging process consists of the power supply, the charging station, the charging cable, and the charger itself, like a chain. The weakest link in this chain always determines the maximum charging power available. If the charger can withstand only 6.6 kW of power, it will not help to “pump” electricity into the batteries with a 22 kW charging station. In addition, under what conditions are the loading times of these charges realized? Is it an external three-phase high-performance charging station or is it at home? It affects the charging time and efficiency.

The charging efficiency of electric vehicles, the weakest of which will determine the maximum charging power, is significantly affected by the ability of EV charging socket outlets to withstand this continuous load when charged at home. EV manufacturers usually advise users to use their own wall box, a separate charging station.

On the other hand, no matter how publicized this is by automobile manufacturers, rapid charging can harm a lithium-ion battery. Short charging times or high charging currents can have a negative effect on the electrode material, shortening service life and cycle times. Therefore, the use of AEC-Q200 compliant protective devices for battery management, charging and discharging electronic devices to prevent overcurrent and overheating of charging devices will be the most important key to the safety of fast charging and the ability to extend battery life. Detailed information for this topic can be found online.

Providing an overall power solution that is safe and easy to use

SCHURTER Group is a Swiss-based global manufacturer of electronic components, providing safe supply of power, ease of use, and sophisticated overall solutions. SCHURTER manufactures and distributes components for circuit protection, as well as connectors, switches, and EMC products, and works closely with customers to provide electronic manufacturing services and solutions, from project planning to end-products manufacturing.

Catering to the automotive industry, SCHURTER is certified according to the new Automotive Standard IATF 16949: 2016 which places the highest demands on the system and process quality of a company, and has developed products and solutions used in applications such as wallboxes, fast charging stations, on-board chargers, emergency charging cables, battery management systems, inverters, ignition systems, emergency power supplies, climate control systems, as well as control elements.

EMC products for fast charging station applications

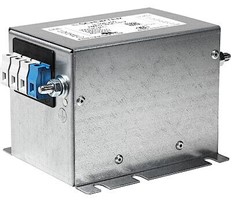

Compact and high-performance single-stage three-phase power filters

SCHURTER's FMAC NEO is a compact and high-performance single-stage three-phase power filter series, which has excellent power filter performance and is suitable for high-EMC load devices such as energy converters or motor drives. Typical applications include converters for photovoltaics, battery storage devices, or EV charging stations. These new high-performance power filters are also a good choice for modern day frequency inverters used for motor control.

FMAC NEO series power filters have screw terminals for safe and reliable wire terminals. All-metal flange guarantees a good earth ground connection upon screw mounting to the chassis. The standard version applies to a wide temperature range, from -40°C to 100°C. These power filters are suitable for a 16A to 230A range of current at ambient temperatures of 50°C, approved to ENEC and cURus standards, and are recommended for applications up to 520 VAC. The standard version is specifically designed for industrial applications with leakage currents below 13 mA. FMAC NEO also provides special versions for applications with leakage currents less than 3 mA.

A completely redesigned FMAC NEO family of product modules is an ideal alternative to SCHURTER for all types of traditional FMAC power filters, with FMAC NEO providing the same high performance at smaller dimensions and lighter weights. The FMAC NEO series uses a compact design, small footprint, efficient single-stage filters, lightweight design, wide temperature range, and expands its performance in many key applications. FMAC NEO can be applied to a rated voltage of 520 VAC globally to prevent interference voltage from the power supply. It is designed for industrial applications, e.g., frequency converters, stepper motor drives, UPS systems, inverters, etc, and is suitable for IEC/UL 62368-1 compliant equipment.

High-performance three-phase power filters with a neutral line

The FMBD EP three-phase power filter by SCHURTER is a double-stage flagship filter family suitable for three-phase with neutral lines systems. Its special models can be used for high-rated voltage applications. The series is suitable for applications with ultra-high EMC emissions, such as equipment and systems for fast charging stations, automatic production, motor drives, and industrial plant machinery. Powerful filters in this series are also the preferred fittings for modern frequency inverters used to control motors.

Due to its particularly compact dimensions and high performance, the new filter series is well suited to today's tight space conditions in machine and industrial plant construction. Due to its high nominal voltage version, it can be applied to a particularly wide range of applications.

The FMBD EP three-phase power filter is more compact than previous generations, and the design of the new almost - cuboidal design takes full advantage of the space in the housing. Due to the use of double-stage filters and the use of the highest quality components, such as dimensioned film capacitors and choke with highly permeable cores, new developments have gained prominence with excellent broadband filter attenuation.

The FMBD EP series has screw terminals, wiring is absolutely safe, with metal flanges to ensure good earth connections when screwed onto the chassis, and its standard type can be used in a wide temperature range from -40°C to 100°C. These filters are specifically designed for currents from 16 A to 230 A at ambient temperatures of 50°C. They are certified by both ENEC and cURus and are recommended for applications up to 520 VAC or 760 VAC and can prevent interference voltage from the power supply. They are specifically designed for industrial applications, such as frequency converters, stepper motor drives, UPS systems, inverters, and are suitable for IEC/UL 62368-1 compliant equipment.

Standard filters for DC systems and photovoltaic converters

SCHURTER’s standard DC filter family FMER SOL are cURus-certified, supporting up to 1000 VDC and an ambient temperature up to 75°C. They are suitable for up to 150 A 600 VDC types and 1000 VDC types above 250 A, and help meet international EMC standards to protect PV modules from inverter emissions.

Modern solar inverters will use MPP (maximum power point) trackers, which will interfere with the AC power cord of the grid and the DC side of the solar module. AC filters are commonly used on grid AC power line, but noise generated on the DC side is often overlooked. However, EMC standards EN 61000-6-3 and EN55014-1 also limit the noise generated by lines not connected to the grid, such as those connected to solar panels, which can be met by using DC filters on the inverter DC side.

Large solar inverters installed in electrical installations typically require a cooling system, providing high-temperature resistant components that simplify the system and reduce the energy required for cooling. FMER SOL filters are designed for 25 A to 1500 A rated currents and voltages up to 1200 VDC at an ambient temperature of 55°C.

FMER SOL DC filters are designed for screw clamps of up to 150 A type and for copper bars of more than 250 A type. Other types of connections, such as wires or copper bars < 250 A, may also be provided upon request, or the circuit or filter housing may be slightly adjusted as required.

Conclusion

Charging efficiency will be one of the elements related to the general public’s acceptance of EVs, but while fast charging is pursued, safety will not be negligible, and power filters will provide a safer power supply. SCHURTER's introduction of multiple power filters to improve charging efficiency and safety will be one of the best options for EV fast charging applications.